Product Focus - ShaxX from Bluebell Opticom

Product Focus - ShaxX from Bluebell Opticom

2 Jan 2021

By

charlielangridge

About Bluebell Opticom

Bluebell Opticom designs and manufactures high-quality infrastructure solutions for the broadcast, telecommunications, and professional AV industries. Its products are used for the critical delivery of video, audio, and data services requiring the transport of high-bandwidth signals over long distances using fibre optic and IP networks. Solutions range from robust stand-alone field deployable products to complex fixed installation solutions

Product Focus - ShaxX - SMPTE Hybrid Alternative Connector Kit for Power Insertion

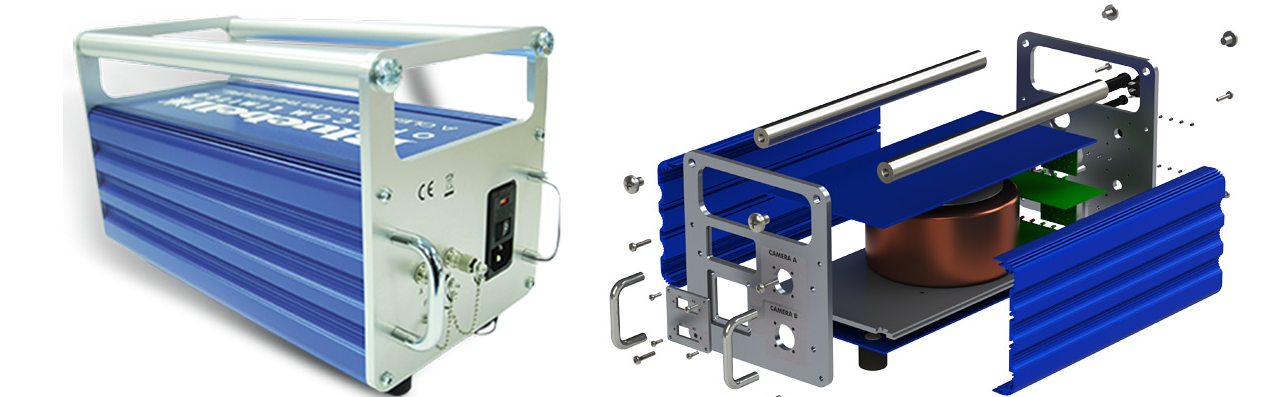

The ShaxX System from Bluebell has been designed to provide power insertion to broadcast cameras fitted with Standard SMPTE 304M hybrid connectors, thus allowing them to be remotely powered over the hybrid cable. The ShaxX allows the camera to be powered from a mains supply remotely located compared to the camera. Power can be inserted and transferred to the remote camera which can be up to 300m away. When combined with the Shax-CCU, cameras can be remotely deployed using the ordinary singlemode optical fibre network that may exist within a stadium. This system allows the user to replace the fibre/copper hybrid cable between the camera and the CCU with standard fibre cable and relay all the communications and signals. This frees the camera from being tethered to a local mains supply. The ShaxX/Shax system is perfect for Stadiums, Arenas and Concert Halls that have preinstalled fibre networks. The ShaxX is enclosed in a robust and ruggedised aluminium enclosure, ideally suited to Outside Broadcast and Fly Away applications. The ShaxX can also be combined with the BC Series Multi-format Interfaces to carry signals from multiple cameras over a single cable. This can help reduce and simplify rigging and installation time. Contact the Sales Office for additional information on the available options. Front panel LEDs give instant operational feedback of the link status between each camera and CCU

Lincoln Binns involvement.

Bluebell Opticon came to Lincoln Binns with a PCB and a hand drawn sketch and handed the enclosure design process over to us.

The design process on this project:

- Initial quotation based on information provided – for approval. The cost may change as the design evolves.

- Set of drawings produced – for approval. These drawing are used to program the CNC machines as well as the laser and printer if required.

- Final quotation if pricing has changed.

The design solution:

- Main body of the enclosure is based on the UnioBox 3 and anodised blue

https://lincolnbinns.com/customisation/custom-aluminium-enclosures/custom-uniobox-enclosures.html

- The front and rear panels are both 5mm thick and oversized to incorporate a handle.

- All cut-outs are milled and include removeable subpanels to allow for different versions to be built from a base design

- Once anodised the front and rear panel are then printed with text

- The top panels is laser etched with company logo and model name

- The kit of components is completed with screws.

- First batch produced 4 weeks from drawing approval

To talk to Lincoln Binns about your customised aluminium enclosure, end plates or accessories, contact the Sales Team

Phone +44 1403 860900 or email info@lincolnbinns.com