Custom Combi-Case Enclosures

- Home

- Custom Enclosures

- Custom Aluminium Enclosures

- Custom Combi-Case Enclosures

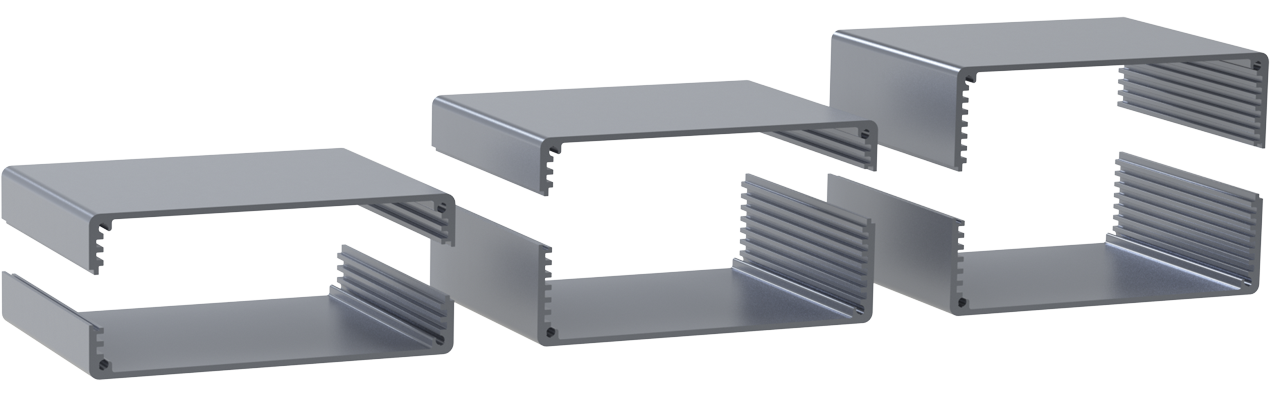

The Combi-Case u-section extrusion can be customised to suit your application

- Custom Options include:

- Extrusion - Length, colour, cut-outs, artwork

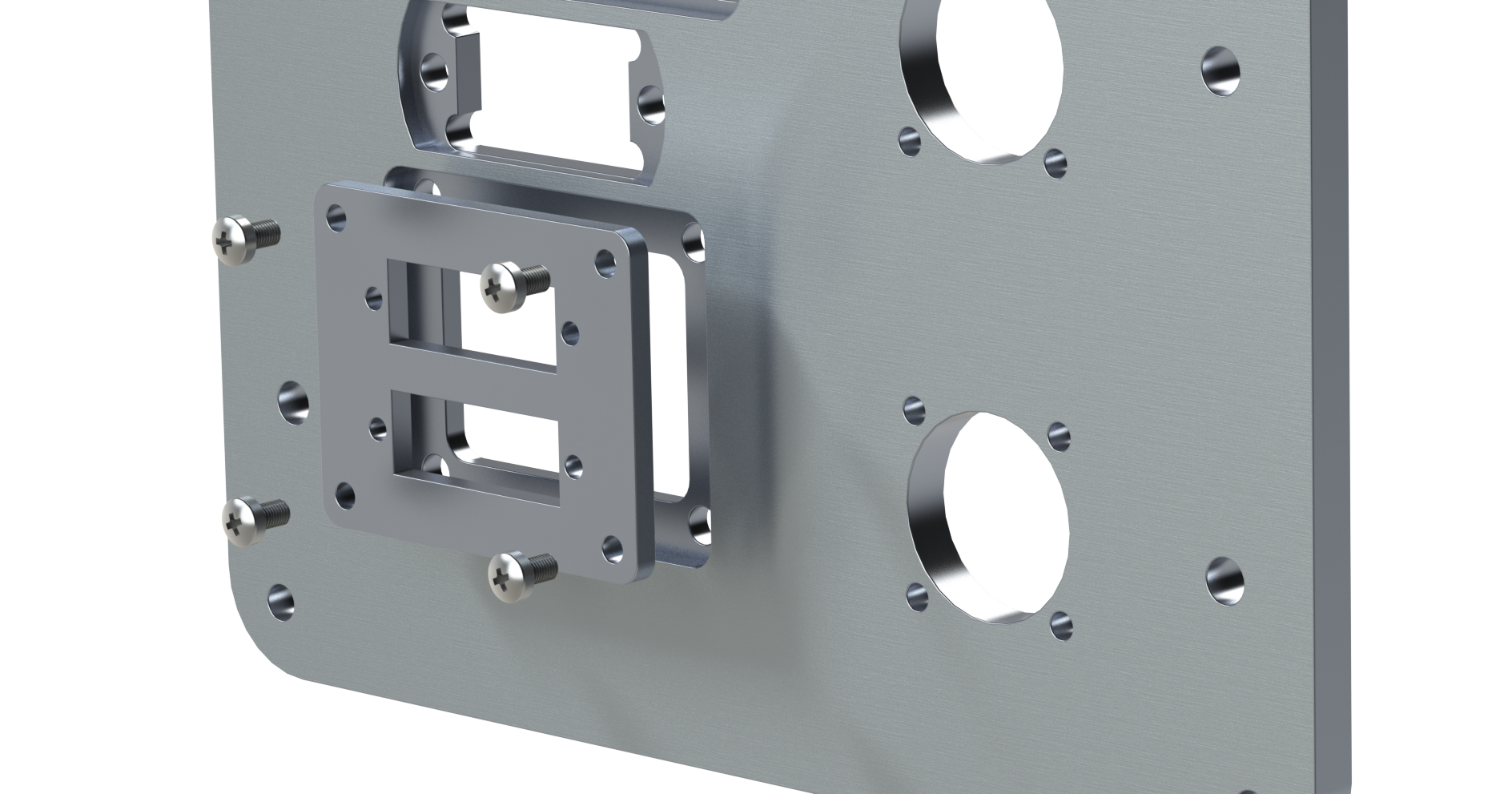

- End Plates - size, thickness, colour, cut-outs, fixings and artwork

- Carrier Plates - size, cut-outs, fixings and artwork

- 100mm wide PCB or carrier plate

- Maximum height of components is 19.6mm

- Weight: 1.88kg/m

Combi-Case 100 x 44mm

- 100mm wide PCB or carrier plate

- Maximum height of components is 33.6mm

- Weight: 2.25kg/m

Combi-Case 100 x 58mm

- 100mm wide PCB or carrier plate

- Maximum height of components is 47.6mm

- Weight: 2.61kg/m

Custom Options

Extrusion

- Can be cut to length: 40mm to 1500mm

- Cut tolerance: -0mm / +0.5mm

- Surface finish: Anodised, Anti-corrosion or Powder Coated

- Milled cut-outs or recesses

- Laser marked or digital print

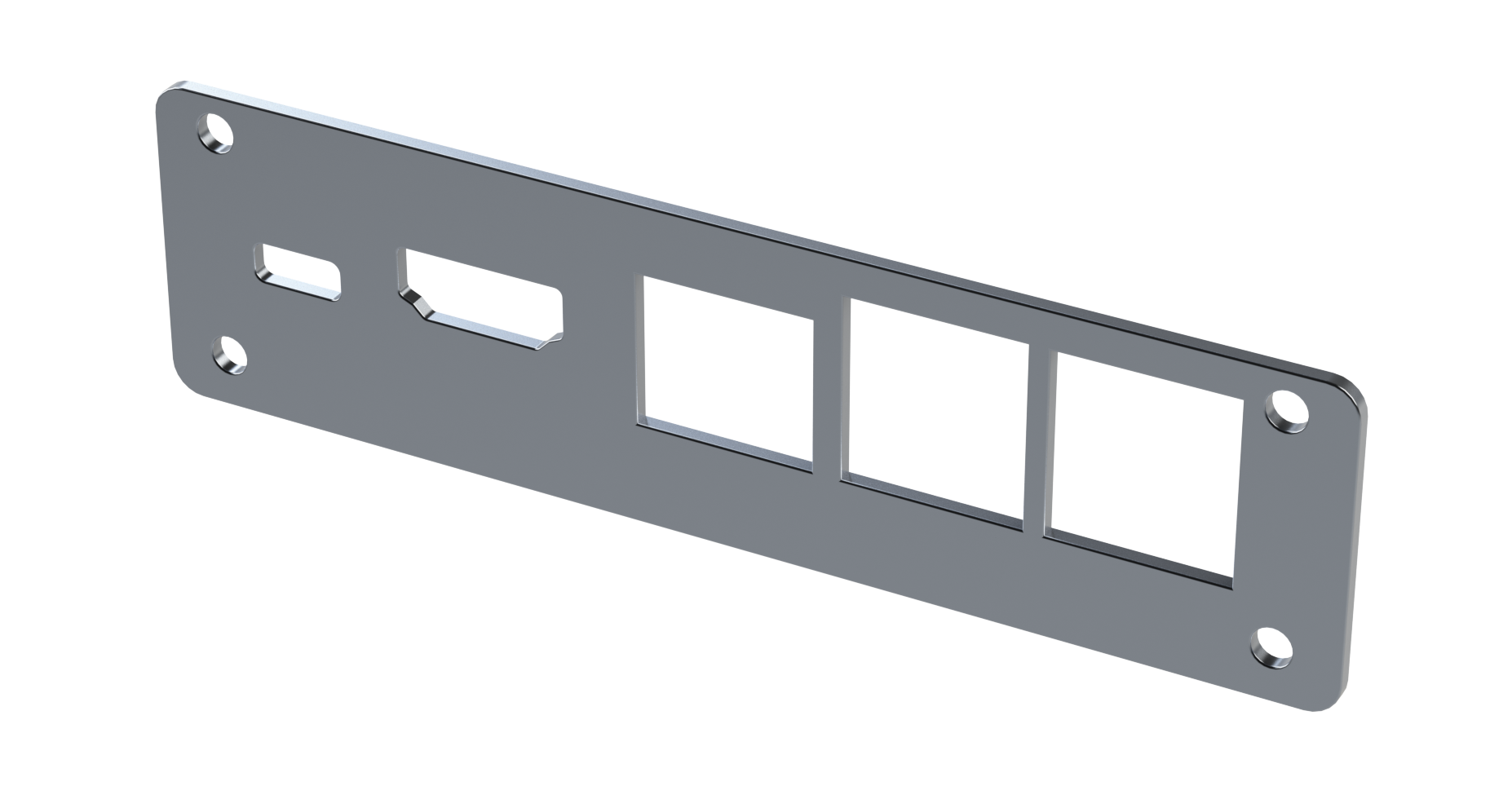

End Plates

- From 1.5mm up to 10mm thickness

- Over sized

- 19″ rack mount

- Aluminium, Zintec or Acrylic

- Various surface finishes and colour options

- Milled or punched cut-outs

- Laser marking or digital print

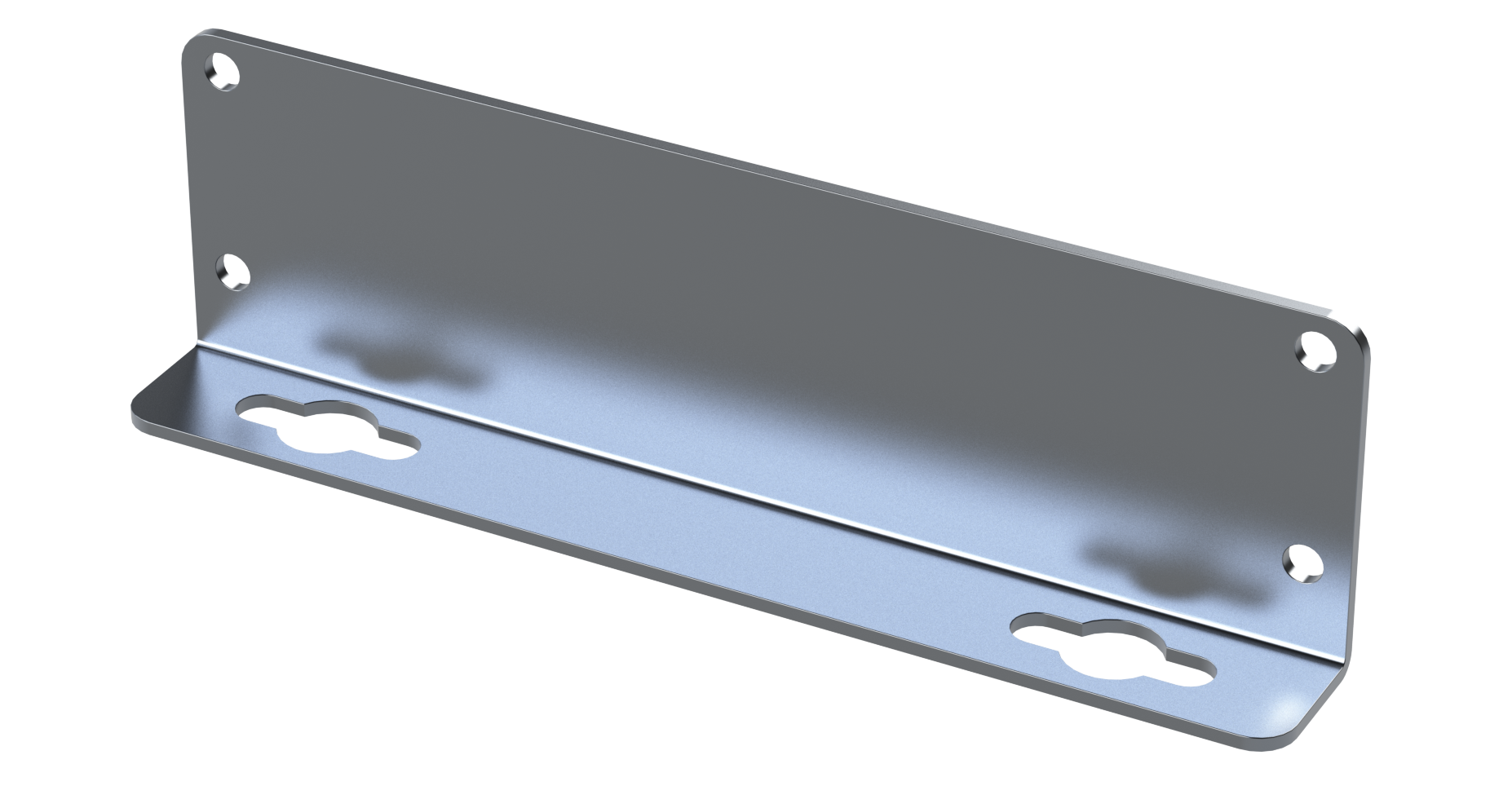

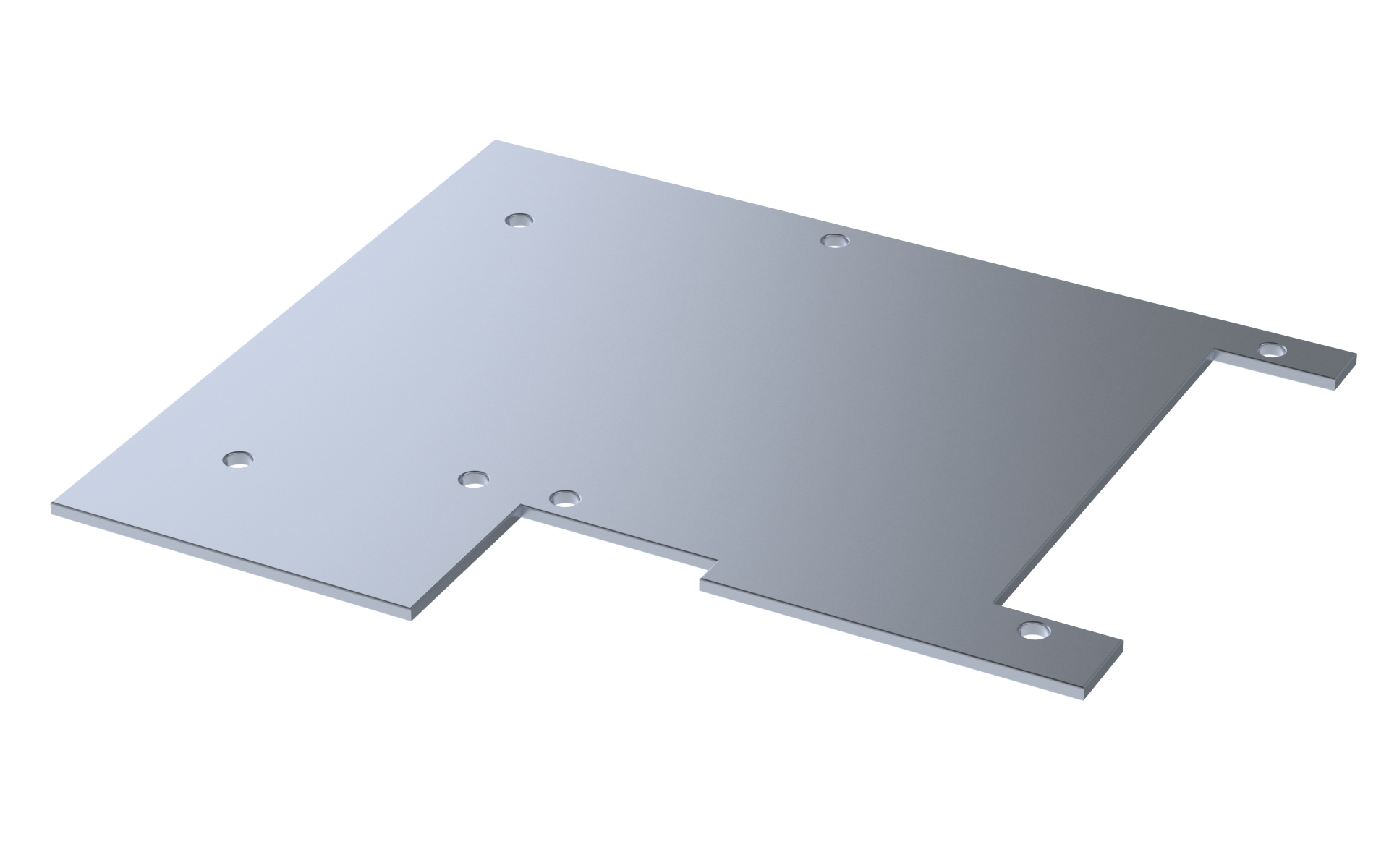

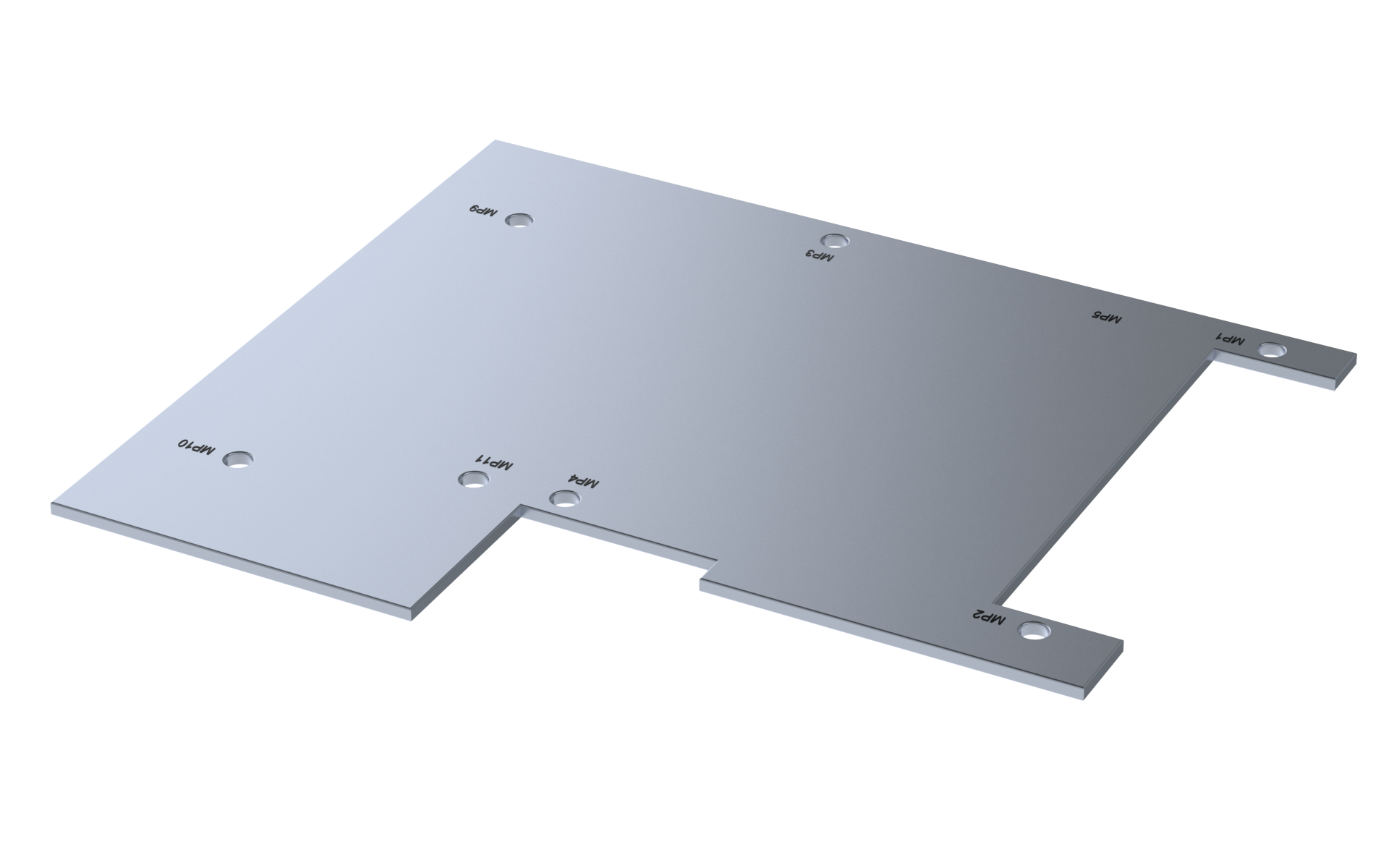

Carrier Plates

- Manufactured to specified dimensions

- Various surface finishes & colour options

- Punched cut-outs

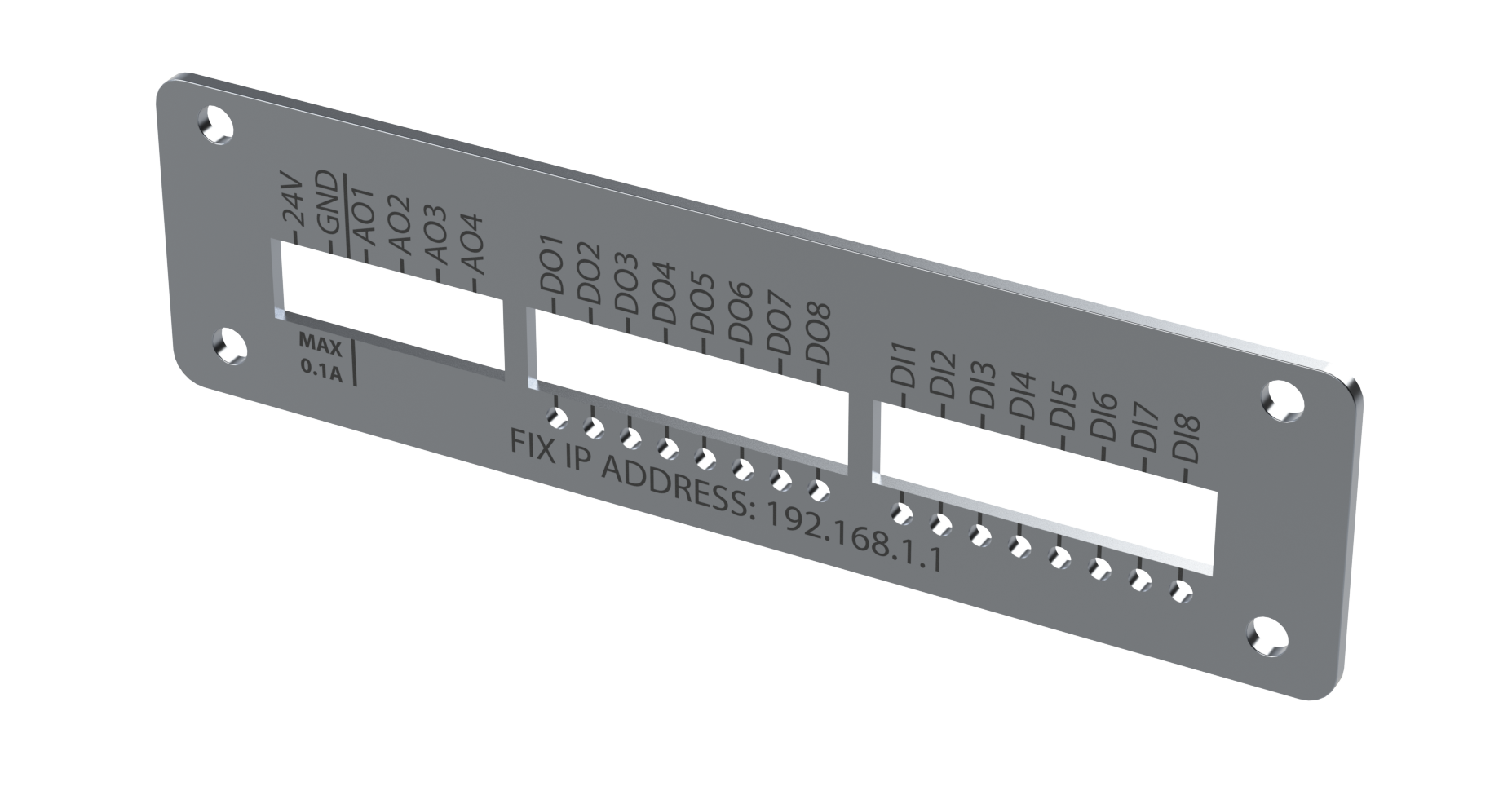

- Laser marked or digital print

Cut to length:

Available in cut lengths from 40mm to 1500mm for UK shipments and 1000mm for standard worldwide shipping. Longer lengths can be shipped but will need to be discussed further.

Cut tolerance: -0mm / +0.5mm

CNC Milling:

Holes for connectors or light pipes and large cut-out for LCD screens can be milled into the extrusion as well as a recess for labels or a membrane.

Please note we will require the following information:

- Full list of the components being used

- Dimensioned drawing. Preferred formats are STEP, IGES, DXF or SolidWorks files but we will work from a hand drawn sketch

Surface Finish:

Anodised Colour Options: Clear (SIlver), Black, Blue, Red, Green. Please call to discuss other options.

The maximum length of extrusion that can be anodised is 1Mtr

Anti-corrosion coatings: Surtec 650 or Iridite NCP

Powder Coating: Fine texture; Black, Red and Grey. Please call to discuss other options. For other colours a RAL number is required

Masking available upon request.

Artwork:

Artwork can be applied to the enclosure in one of 2 methods:

- Full-colour Digital Print

- Laser Marking

Please note we will require the following information:

- For best results, we will need you to provide us with logos and icons in a vector format.

- A list of all fonts used.

Material Options

All of our standard end plates are Aluminium, however we can supply end plates in Zintec if you require a thinner plate or from acrylic if you need Bluetooth or Wi-Fi connectivity

Material Options - Thickness:

Aluminium:

Standard sizes: 1.5mm (E-Case A, B & C) and 2mm (E-Case D) thickness.

Thinner end plates, down to 0.9mm

Thicker: end plates, up to 12mm

Zintec: - Can be manufactured from 0.7mm up to 3mm

Acrylic: - Can be manufactured from 3mm to 12mm

Cut-outs:

Depending on the thickness of the end plate – see below, we will either CNC Punch, Mill or Laser cut the panel. Holes can be straight through, counter-bored or counter-sunk.

Please note we will require the following:

- A full list of the components being used.

- Dimensioned drawing. Preferred formats are STEP, IGES, DXF or SolidWorks files but we will work from a hand drawn sketch

Flanged Plates:

The end plates can also be folded 90 degrees to act as a foot or for surface mounting

Plates up to a thickness of 5mm can be cut and folded

Oversize Options:

Standard end plates are the same width and height as the extrusion but we can manufacture the plate oversize

- This could be so that the front plate is used as a fixing option in a control panel

- The panel can be taller with a cut out to act as a handle

- To sit below the extrusion to act as a foot or shaped to form feet

Sub-Panels:

On end plates thicker than 3mm we can cut through and recess a hole complete with clinch fasteners – see below, to fit a sub-panel.

Please note we will require the following:

- A full list of the components being used.

- Dimensioned drawing. Preferred formats are STEP, IGES, DXF or SolidWorks files but we will work from a hand drawn sketch

19" Rack Mount Options:

The front panel can be manufactured so that the enclosure can be mounted into a 19″ rack

Standard sizes: 1U, 2U and 3U

Depending on which E-Case is used, up to 3 units can be mounted side by side

Larger sizes available upon request

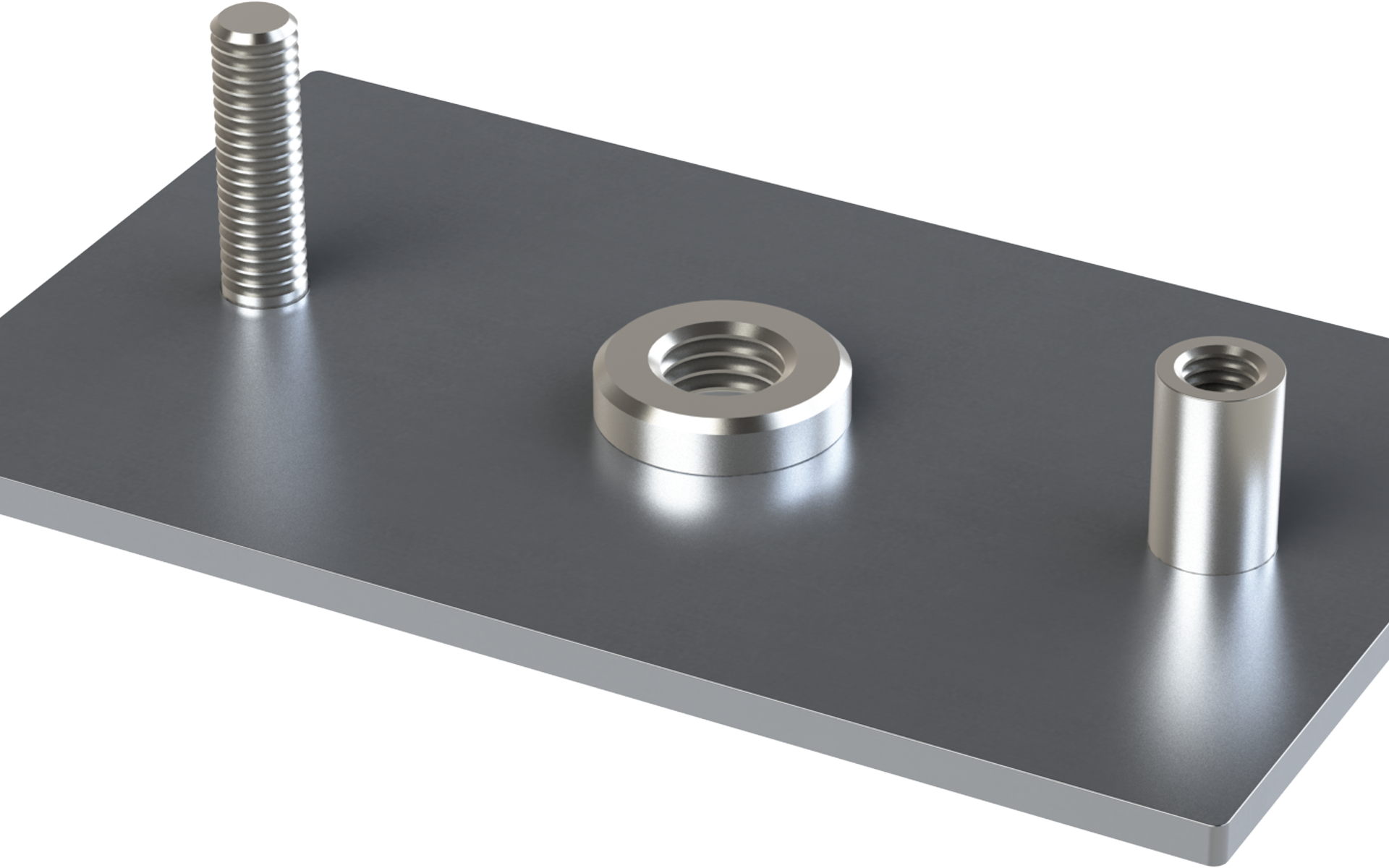

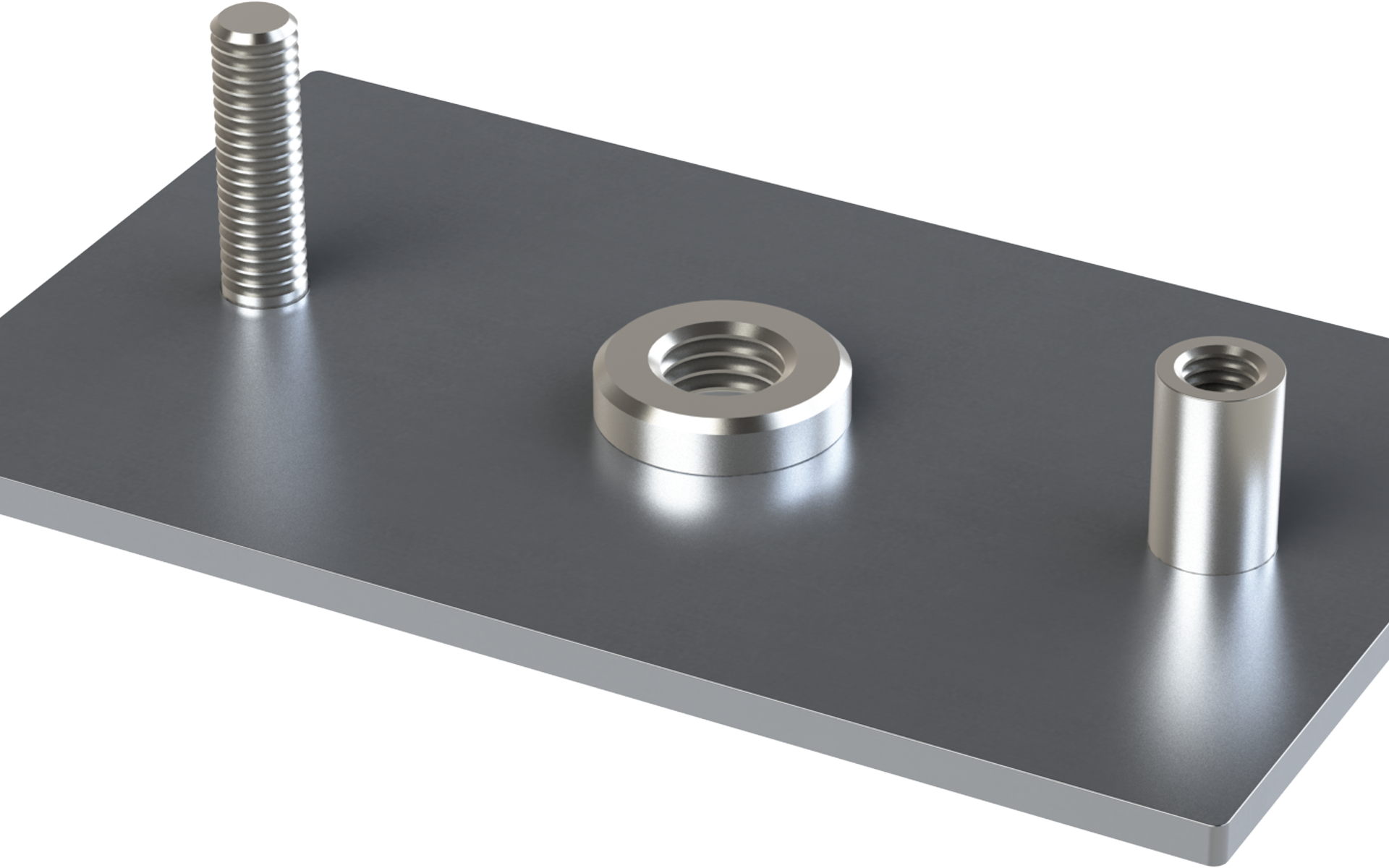

Clinch Fasteners:

A range of bushes, nuts and stand-offs can be added either as a means to mount your PCB or additional components or a grounding point.

Please note we will require the following:

- A full list of the fastenings being used.

- Dimensioned drawing. Preferred formats are STEP, IGES, DXF or SolidWorks files but we will work from a hand drawn sketch

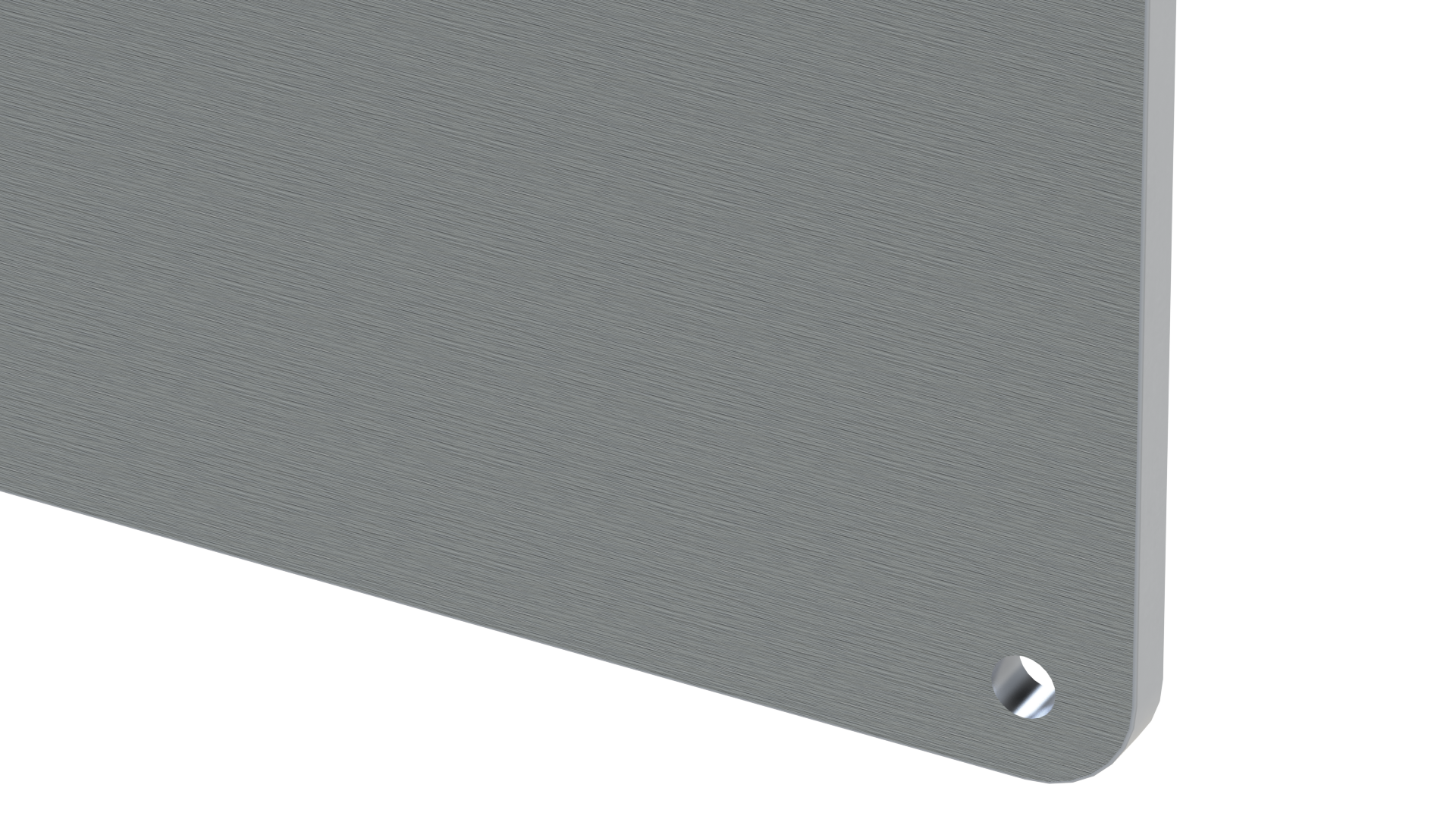

Surface Finish Options - Brushed:

All end plates 3mm or thicker are made from raw aluminium and will, therefore, go through a brushing (graining) process prior to the surface finish is applied.

Finish:

Andodised colour options: Silver, Black, Blue, Red, Green. Please call to discuss other options.

Anti-corrosion coatings: Surtec 650, Iridite NCP

Powder coating: Fine texture. Black, Red and Grey. Please call to discuss other options. For other colours, RAL numbers will be required

Masking available upon request.

Artwork:

Artwork can be applied to the end plates in one of 2 methods.

- Full-Colour Digital Print

- Laser Marking

Please note we will require the following:

- For best results, we will need you to provide us with logos and images in a vector format.

- A list of all fonts used

Thickness Options:

Aluminium:

Standard sizes: 1.5mm or 2mm

Thicker carrier: plates, up to 12mm

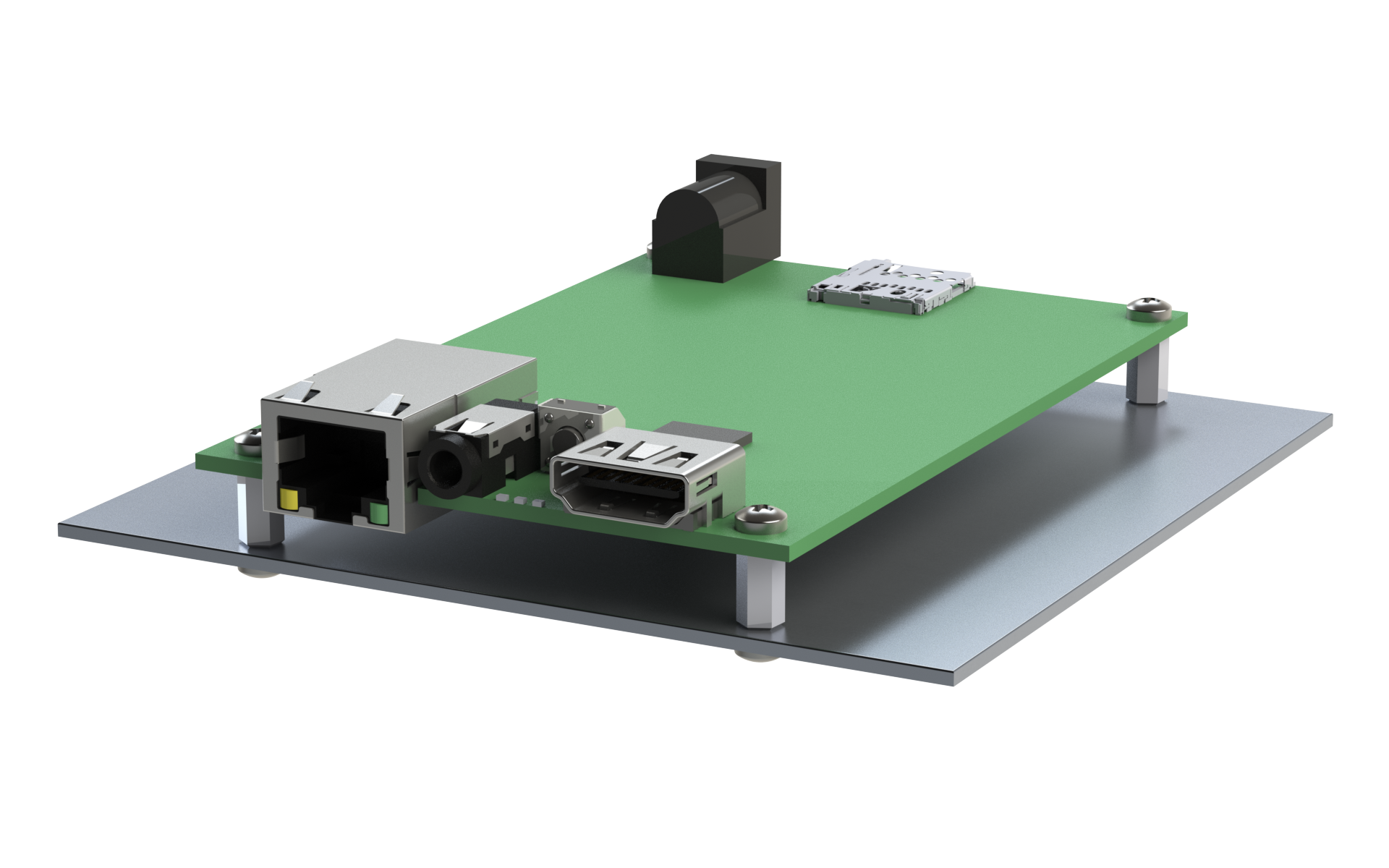

Cut-outs:

Cut-outs can be added for mounting the PCB and other components within the extrusion. Cut-outs can be added to give clearance to other components.

Please note: We will require a full list of the components being used. A dimensioned drawing. Preferred formats are STEP, IGES, DXF or SolidWorks files but we will work from a hand drawn sketch

Positioning:

The carrier plate can be used in one of two ways.

Below with the PCB and components mounted above

Above with the PCB and components hanging below

Clinch Fasteners:

A range of bushes, nuts and stand-offs can be added either as a means to mount your PCB or additional components or a grounding point.

Please note we will require the following:

- A full list of the fastenings being used.

- Dimensioned drawing. Preferred formats are STEP, IGES, DXF or SolidWorks files but we will work from a hand drawn sketch

Surface Finish:

Anodised Colour Options: Clear (SIlver), Black, Blue, Red, Green. Please call to discuss other options.

Anti-corrosion coatings: Surtec 650 or Iridite NCP

Artwork:

Artwork can be applied to the carrier plate in one of 2 methods.

- Full-Colour Digital Print

- Laser Marking

Please note we will require the following:

- For best results, we will need you to provide us with logos and images in a vector format.

- A list of all fonts used.

Combi-Case 100 x 30

File Downloads

File Downloads

Combi-Case 100 x 44

File Downloads

File Downloads

Combi-Case 100 x 58

File Downloads

File Downloads

To download 3D Models in STEP file format you must be registered and logged in

If you have a project or need help with a design - please get in touch

Send us a message

Contact Us

- Oakendene Industrial Estate

Cowfold

West Sussex

RH13 8AZ

United Kingdom - info@lincolnbinns.com

- 01403 860900

-

Monday - Thursday 9:00-17:00

Friday 9:00-13:00