Customisation of the E-Case Range

Customisation of the E-Case Range

21 Jan 2025

By

Alan Low

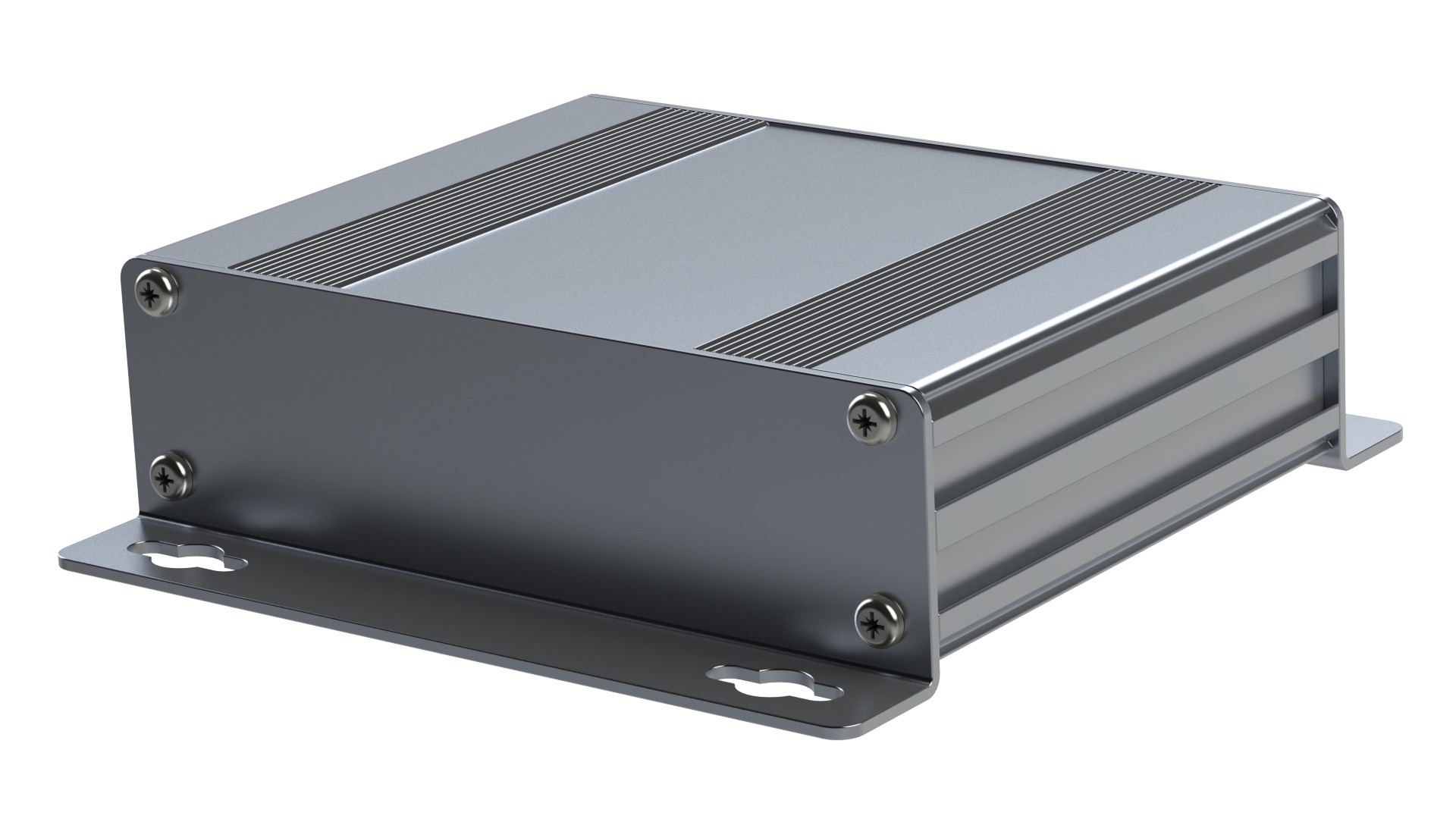

The E-Case range of closed box extrusions comes in five sizes to accommodate PCBs or carrier plates that are 55mm, 100mm, or 160mm wide. These extrusions are available for purchase through our online shop in pre-anodized silver or black finishes, featuring raw edges, and are offered in fixed lengths. Each package includes end plates and screws.

Full customisation of the extrusion, end plates, and carrier plates can be utilised to produce a bespoke enclosure for your product.

Extrusion

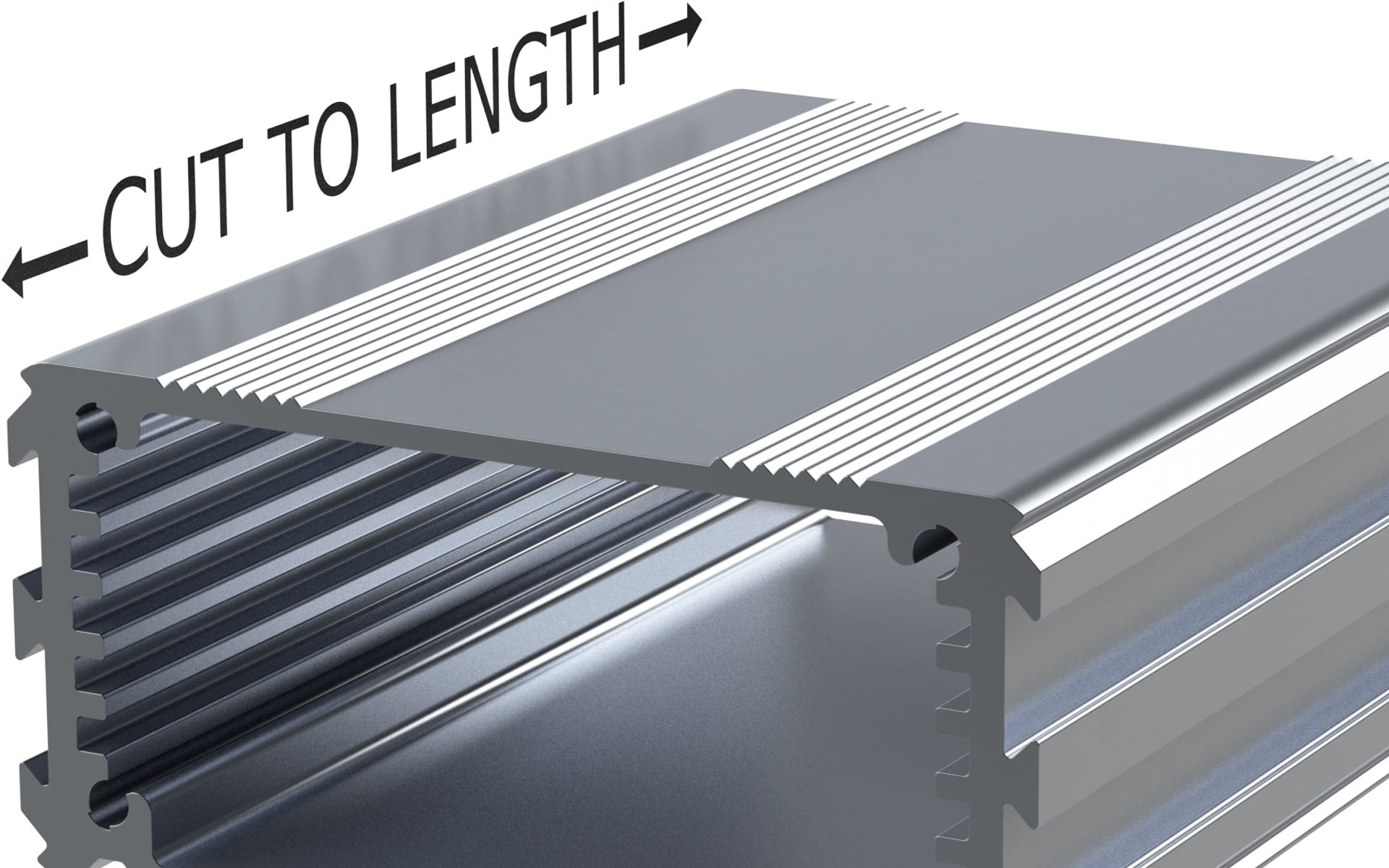

Cut to length

Extrusion is held in stock in pre-anodised silver and black in 3.2Mtr lengths.

The extrusion can be cut to the length required to match your PCB or carrier plate.

The cut tolerance is -0 / +0.5mm

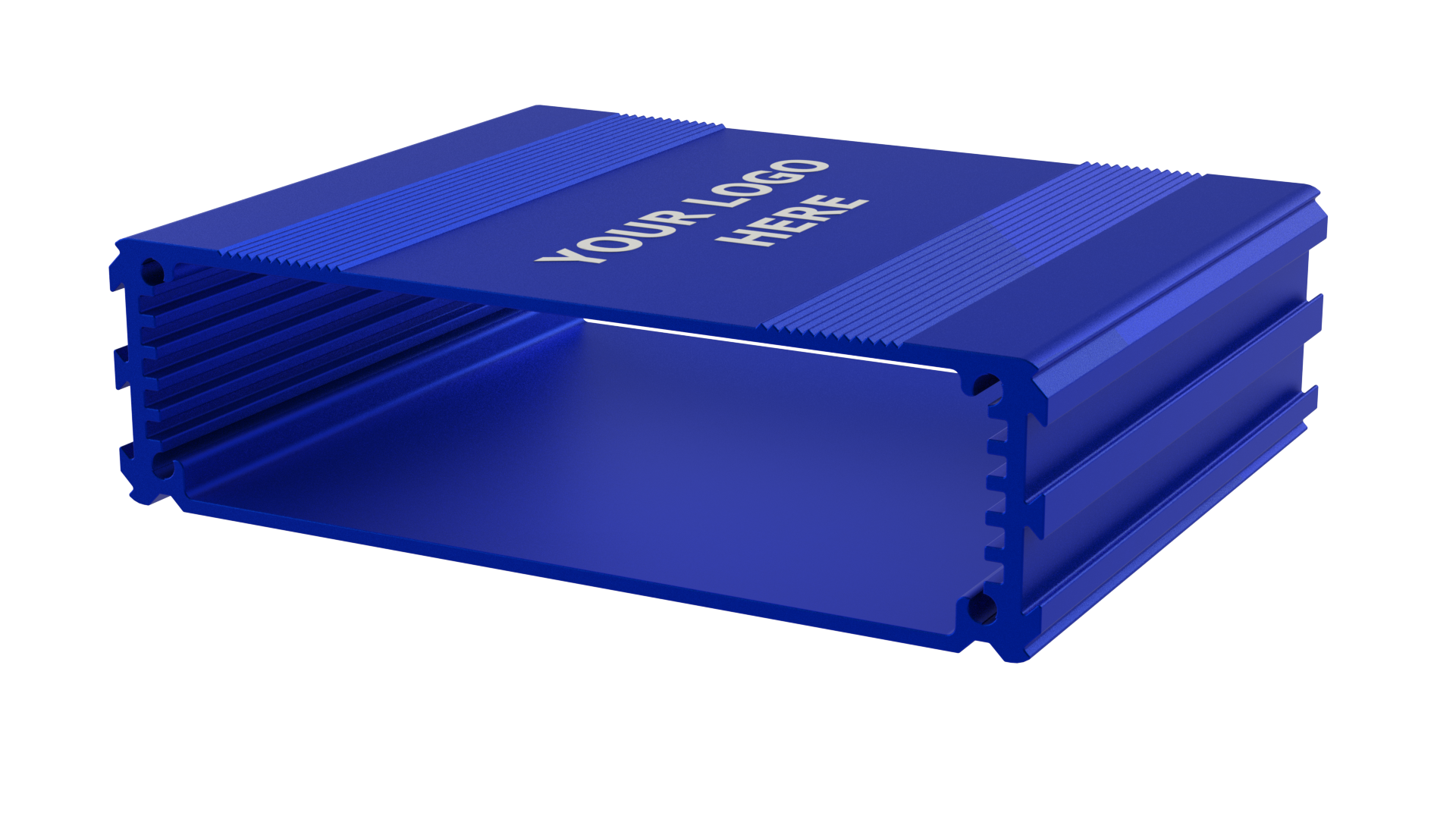

Anodising

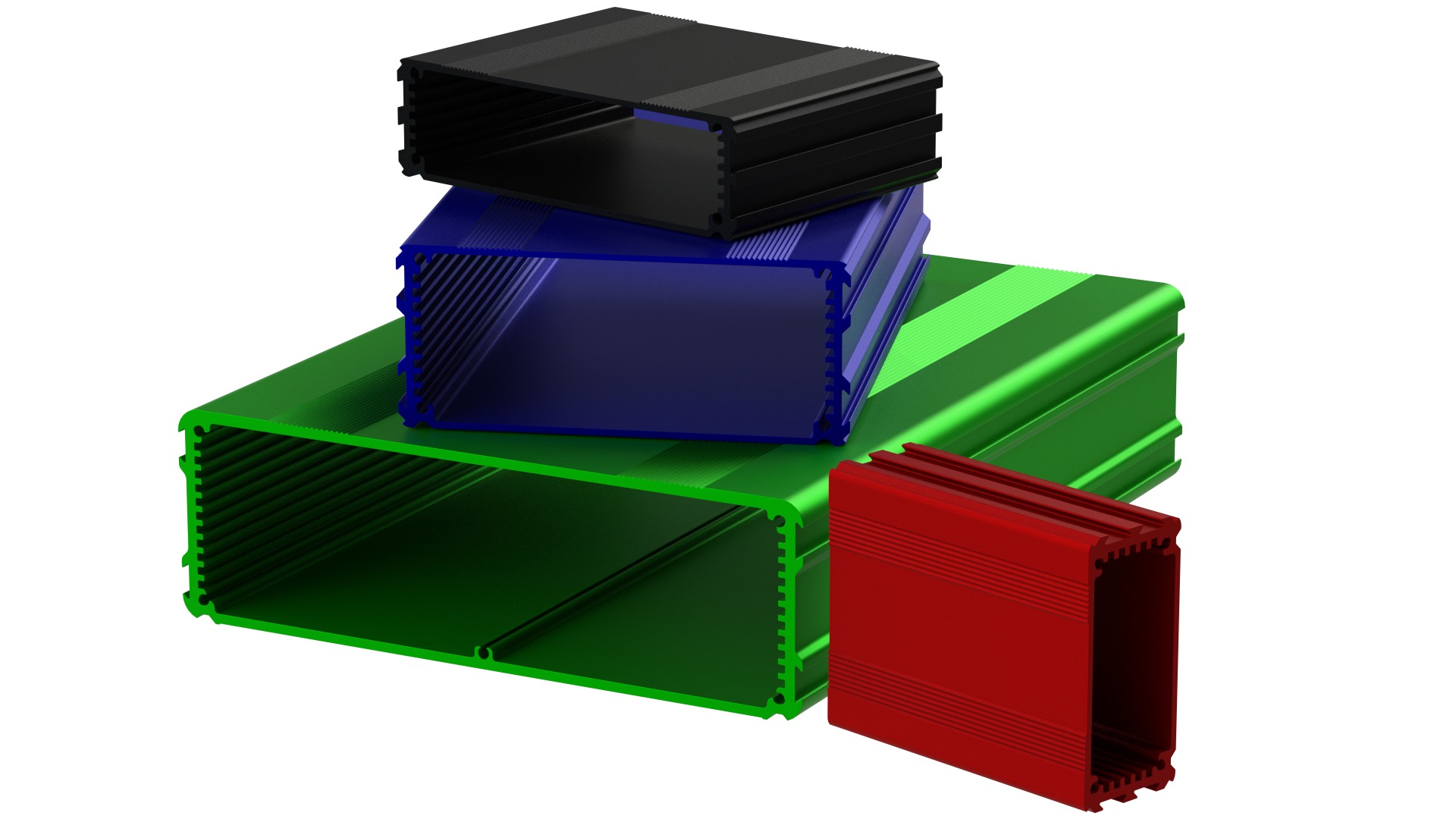

A wide range of anodised colours can be applied to the E-Case range.

Silver (clear), Black, Blue Green or Red

Note: Anodising is a shading process and therefore it cannot match a RAL colour

Other surface finish options

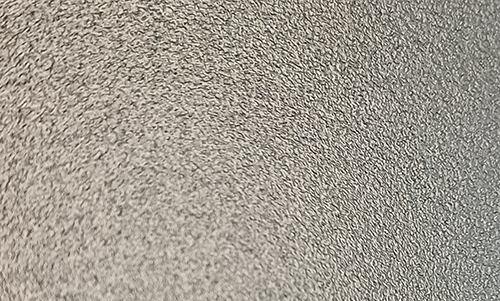

Fine Texture Powder Coating - Please provide a RAL number for the required colour. This may incur additional costs if a batch has to be bought in specially

Conductive Coating - Surtec 650

We can also supply the extrusion with no finish (raw)

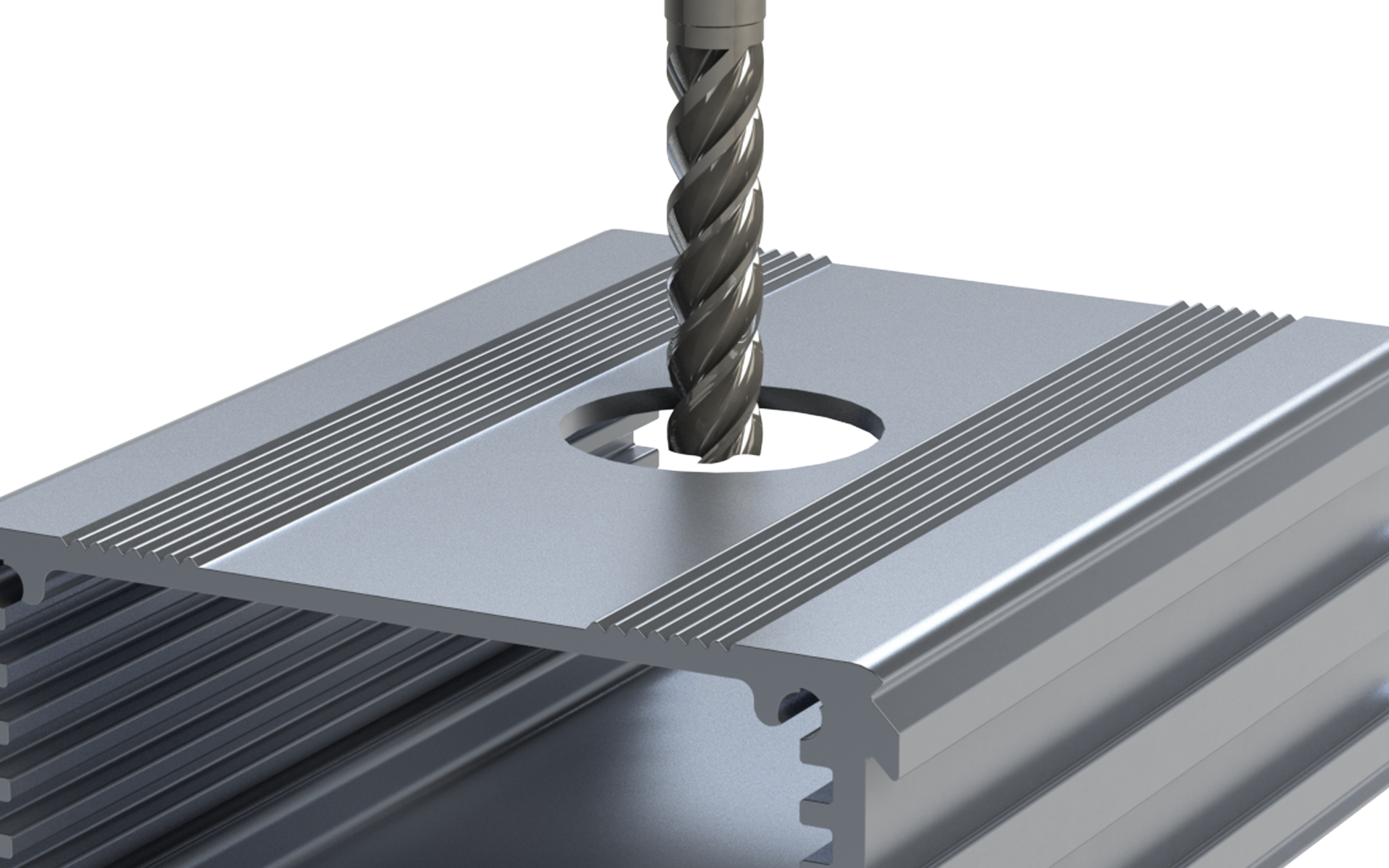

CNC Milling

A wide range of options is available:

Cut-outs for connectors, knobs, or vent patterns,

Keyhole slots for wall mounting

Recesses for labels or membranes

Note: all cut-outs will have a minimum of a 1mm radius in the corners

Digital Printing

Company logos and legends can be full-colour to match your company branding

The UV-cured print can be applied to the top of the enclosure between the ridges.

Note: we will need a vector of any logo and the name of the font to be used

Laser Etching

Laser etching produces artwork in white that cannot be removed from the surface.

Although the process removes the colour from the anodise, it does not remove the anodise itself.

Note: Vectors of logos and font names are needed for this process as well

End Plates

End plates can be manufactured that are taller and or wider than the case profile.

The plate thickness can be increased up to 10mm from the standard 1.5mm

The plate can be laser cut and bent to create a foot for surface mounting.

Alternatively, the plate could be bent at the ends to create a bump bar to protect connectors from knocks

The thicker, oversized end plates can also be recessed at the rear to hide the ends of the case extrusion

Manufacturing Processes

CNC Punching

Plates up to a thickness of 3mm can be punched from a flat sheet.

For best results, each holes need to be punched from a single hit.

Note: This may require a tool purchase for odd shapes

CNC Milling

A wide range of options is available:

Cut-outs for connectors, knobs, or vent patterns, countersink and counterbores

Recesses for labels or membranes

Note: all cut-outs will have a minimum of a 1mm radius in the corners

Laser Cut

Laser cutting is used for thick plates, complicated cut-out patterns, or when the plate is then to be folded.

Note: All laser-cut plates will have some graining on the surface to remove any blemishes

Under certain circumstances, more than one process will be utilised in the production of an end plate.

Illustrated below are some possible end plate customisations

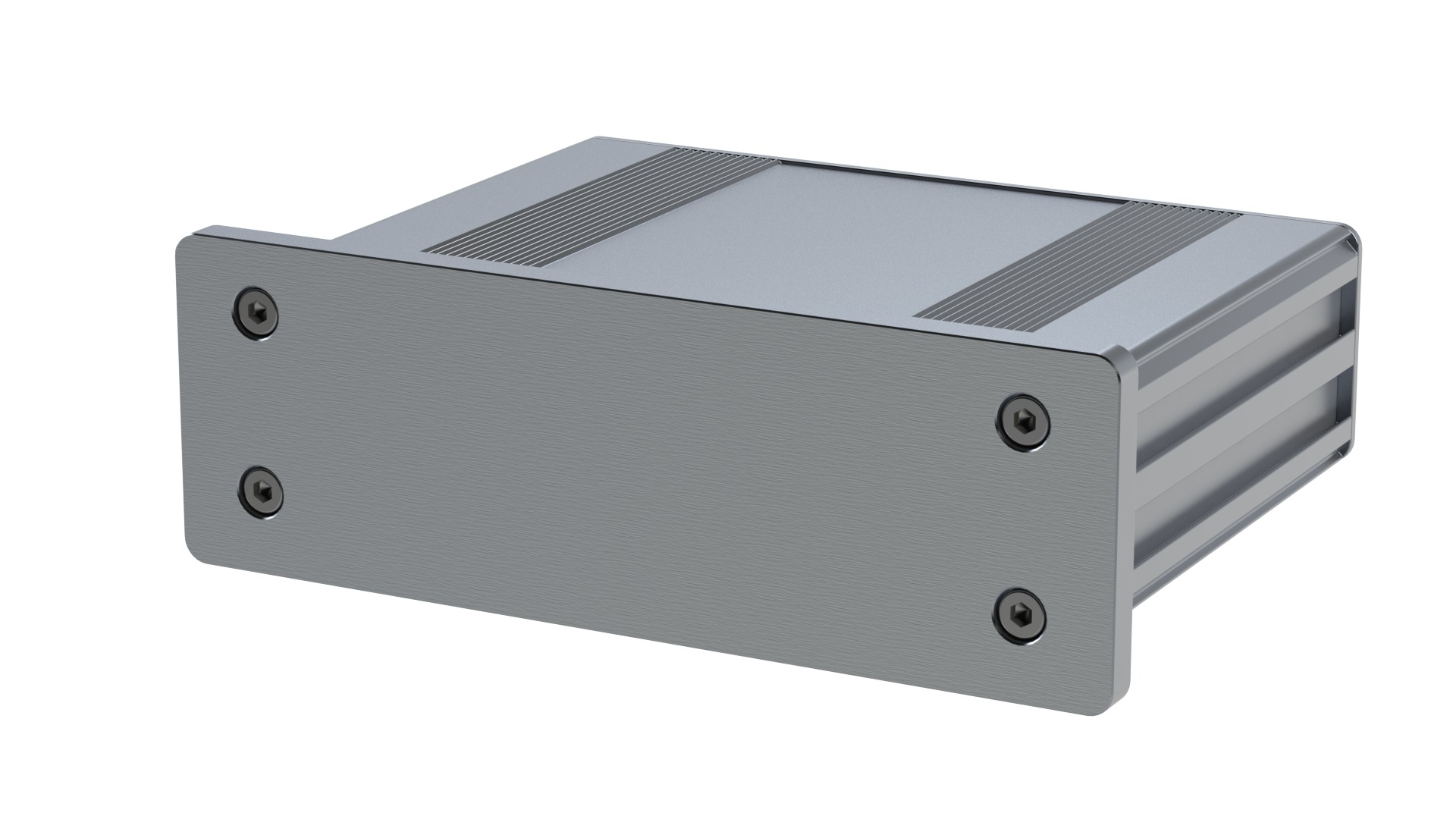

Bent Foot Plate

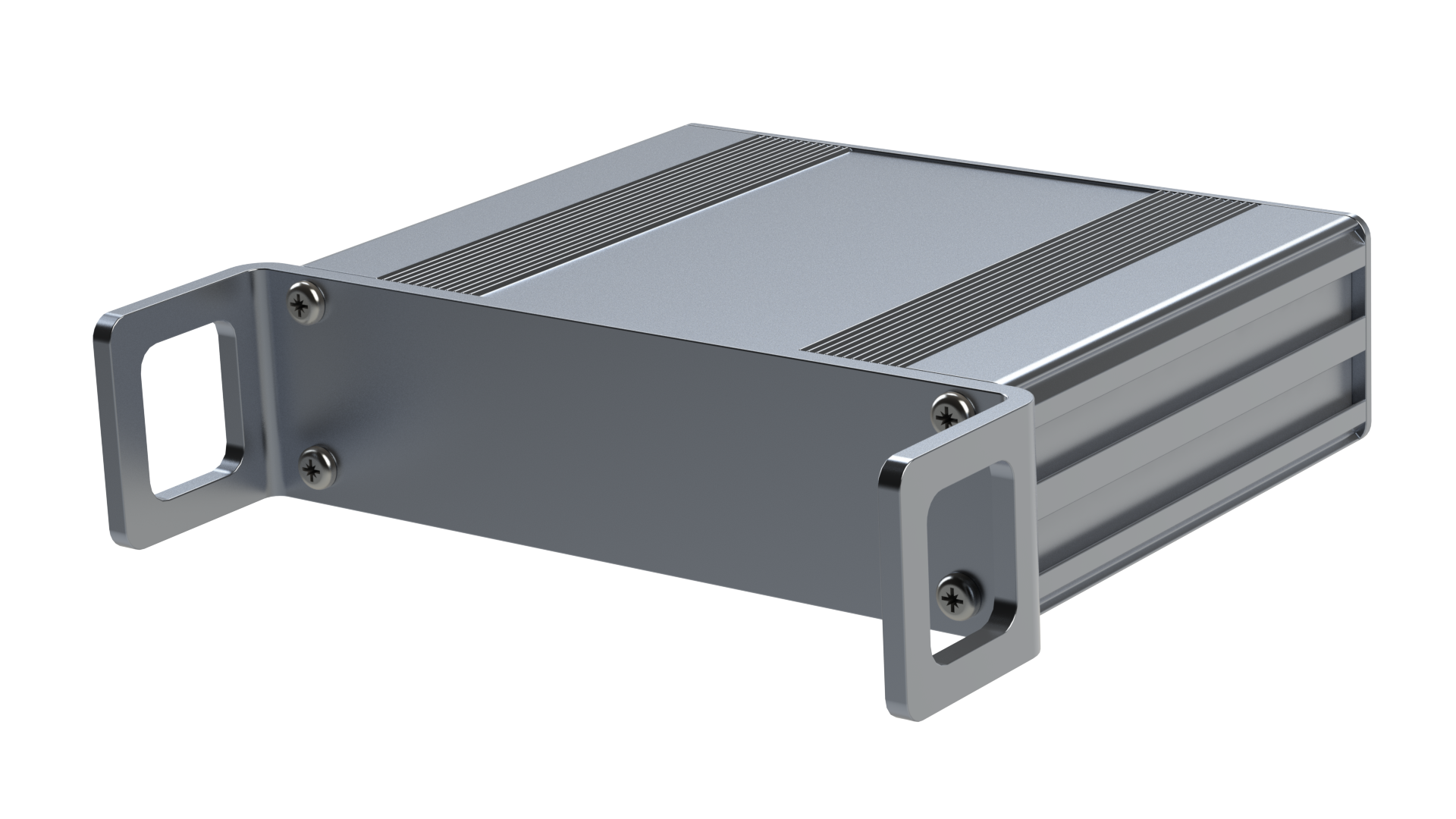

Over-Sized Plate

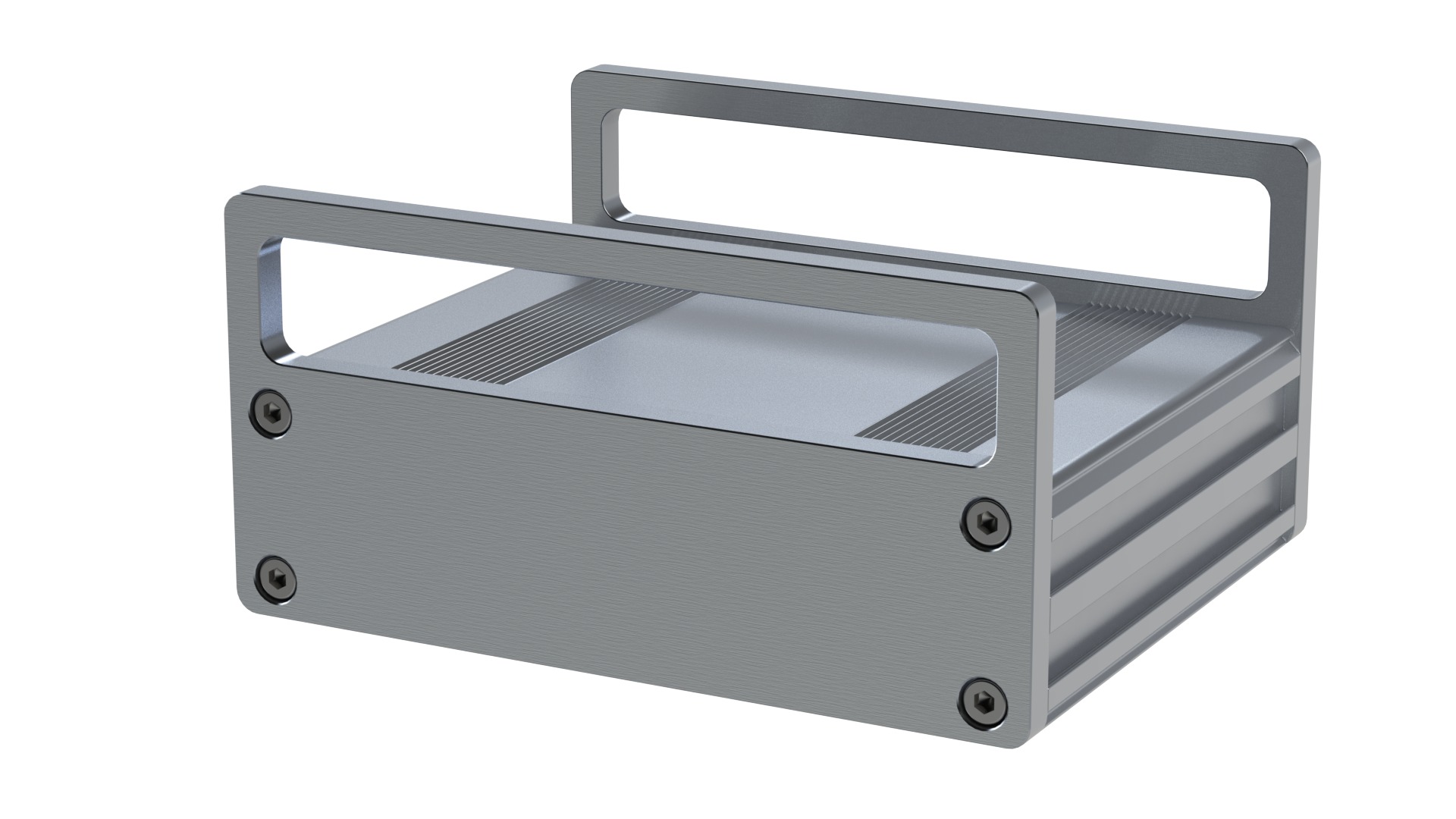

Bump Bar

Handles

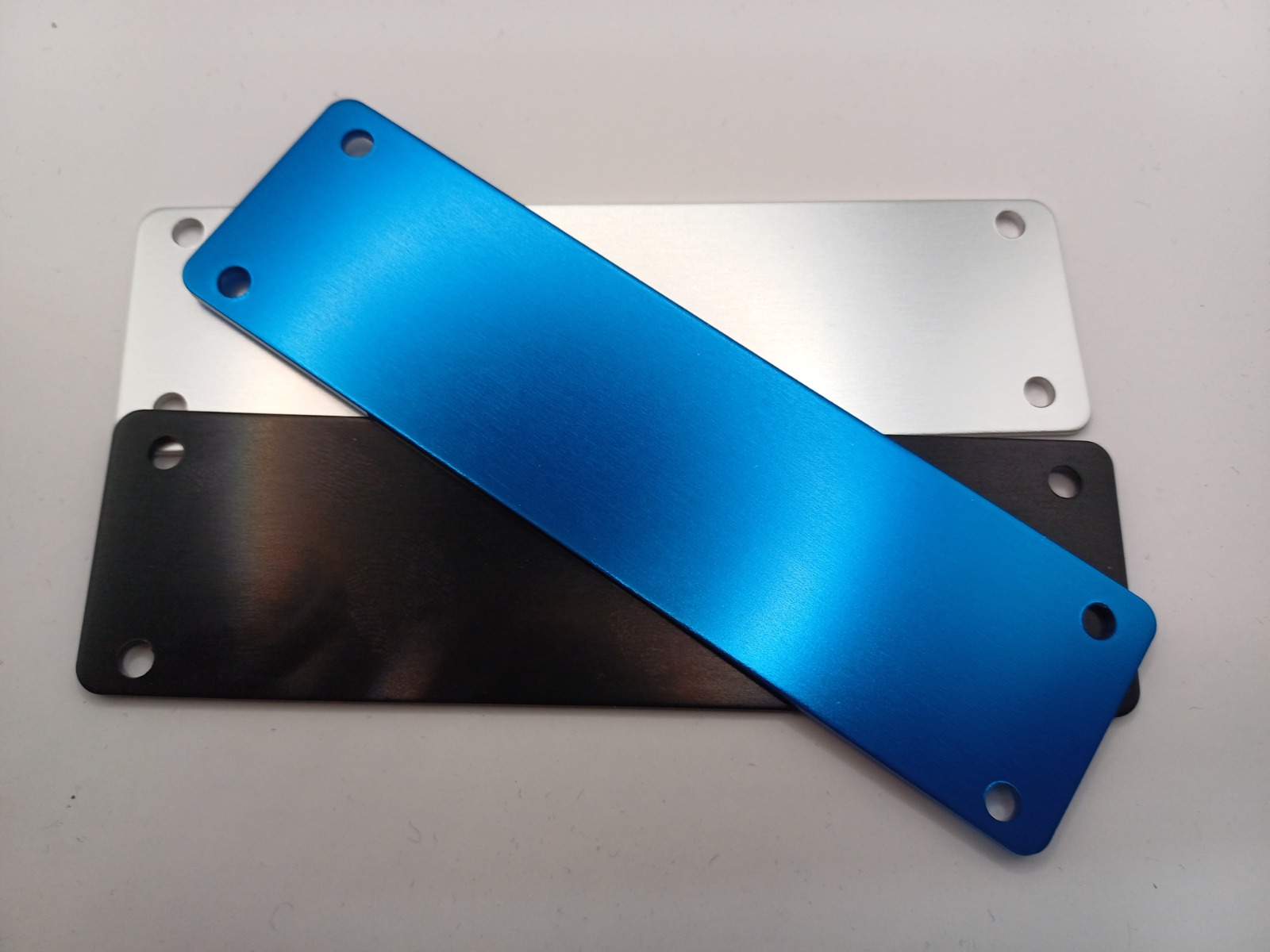

Anodising

A wide range of anodised colours can be applied to the E-Case range.

Silver (clear), Black, Blue Green or Red

Note: Anodising is a shading process and therefore it cannot match a RAL colour

Surface Finish

Fine Texture Powder Coating - Please provide a RAL number for the required colour. This may incur additional costs if a batch has to be bought in specially

Conductive Coating - Surtec 650

We can also supply the end plates with no finish (raw)

Brushing / Graining

1.5mm and 2mm thick end plates are usually made from a pre-anodised sheet with the outer face protected from marking. However, thicker plates are made from raw billet and the face needs to be brushed to remove any marks made during production

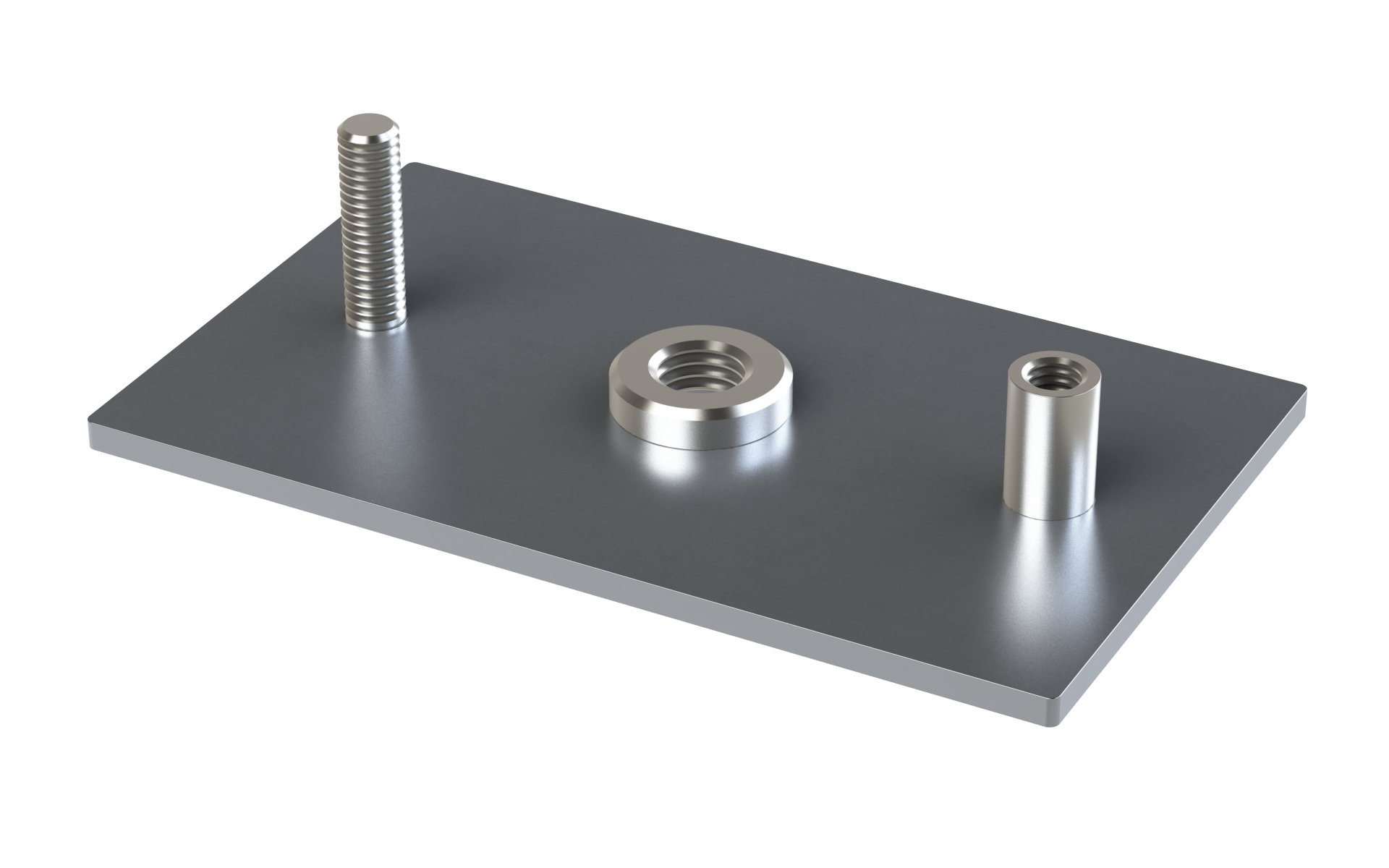

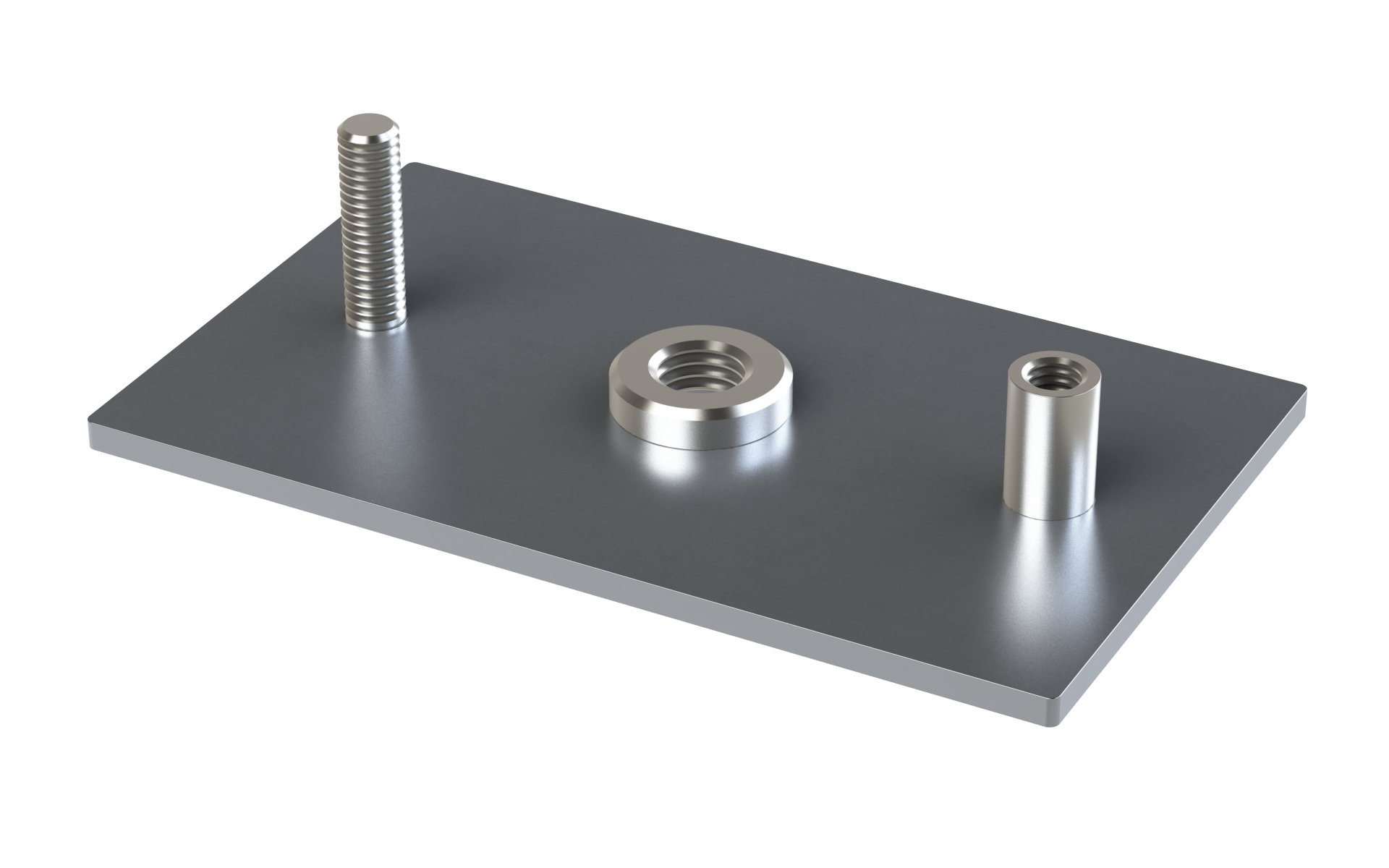

Inserts

Studs, nuts, and stand-off clinch fasteners can be fitted to the end plates for earthing or mounting PCB's, LCD and other components

Digital Printing

Company logos and legends can be full-colour to match your company branding

The UV-cured print can be applied to the top of the enclosure between the ridges.

Note: we will need a vector of any logo and the name of the font to be used.

Laser Etching

Laser etching produces artwork in white that cannot be removed from the surface.

Although the process removes the colour from the anodise, it does not remove the anodise itself.

Note: Vectors of logos and font names are needed for this process as well

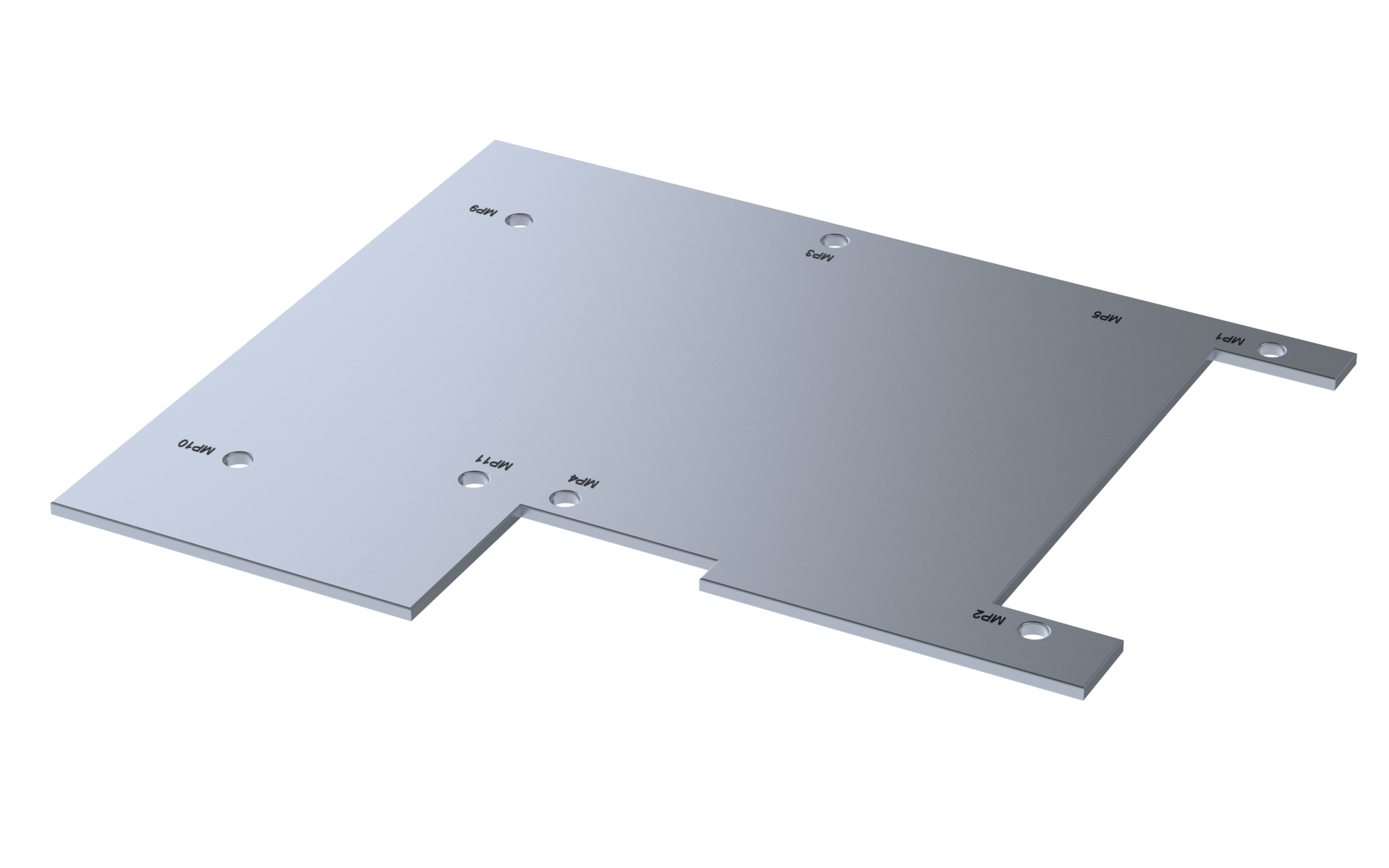

Carrier Plates

Carrier plates can be manufactured to hold the PCB in place when it is not wide enough to fit into the PCB mounting slots on the inside of the extrusion.

Depending on the board design the carrier can be used to sit the board onto or hang the board from.

Digital Printing

Legends and/or assembly instructions can be printed if needed.

The UV-cured print can be applied to the top of the enclosure between the ridges.

Note: we will need a vector of any logo and the name of the font to be used..

Inserts

Studs, nuts, and stand-off clinch fasteners can be fitted to the end plates for earthing or mounting PCB's, LCD and other components

If you would like to discuss any of the above options with a member of our team, please give the office a call - 01403 860900

Download CAD files

Download the Technical Leaflet

Contact us for more information