More Than Just An End Plate

More Than Just An End Plate

12 Jan 2020

By

Alan Low

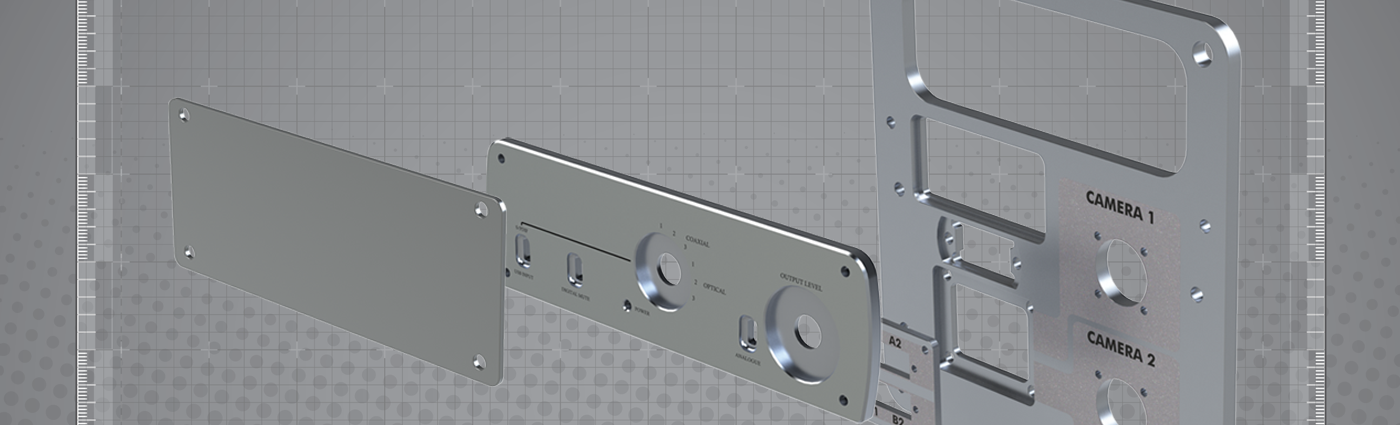

End plates can do more than just seal the end of your enclosure. It can be a canvas for your corporate branding and can be customised to make your product stand out from the crowd.

When designing the end plate there are four mains criteria to consider; Material, Mechanical, Surface finish and Artwork

By working with our sales and design team we can talk you through all of the options that Lincoln Binns can offer, listed below, so please feel free to give us a call or an email.

Material Options:

All of our standard end plates are Aluminium, however we can supply end plates in Zintec if you require a thinner plate or from acrylic if you need Bluetooth or Wi-Fi connectivity

Mechanical Options:

Thickness:

- Aluminium - 1.5mm as standard, can be manufactured from 0.9mm to 12mm

- Zintec - Can be manufactured from 0.7mm to 3mm

- Acrylic - Can be manufactured from 3mm to 12mm

Cut-outs:

- Depending on the thickness and material used we will either CNC Punch, Mill or Laser cut the end panel

- Cut-outs can be through holes, counter-bored or countersunk

Flanged:

- The end plate can be folded 90 degrees to act as a foot or for surface mounting

- Plates up to a thickness of 5mm can be cut and folded – Aluminium and Zintec

Over-sized:

- Standard end plates are the same width and height as the extrusion but we can manufacture the plate over size, which would allow the front plate to be used as a fixing option in a control panel

- The panel can be taller with a cut out to act as a handle or sit below the extrusion to act as a foot or shaped to form feet

Sub-panels:

- On end plates thicker than 3mm we can cut through and recess a hole complete with clinch fasteners, to fit a sub-panel

Recessed Rear:

- If the end plate is both over-sized and more than 5mm thick then we can mill out a recess in the rear of the panel to take the extrusion to give a seamless finish

19" Rack:

- The front panel can be made so that the enclosure can be mounted into a 19” rack

- Standard sizes are 1U, 2U or 3U but we can manufacturer larger sizes upon request

Clinch Fasteners:

- A range of bushes, nuts and stand-offs can be fitted to mount PCB’s, LCD’s etc or to act a grounding point

Please note we will require the following:

- Full list of the components, connectors and fasteners being used.

- Dimensional drawing. Preferred formats are STEP, IGES, DXF file but we can work from a hand drawn sketch

Surface Finish:

Brushing:

- All aluminium end plates thicker than 3mm are manufactured from a raw sheet and will therefore go through a brushing (graining) process prior to the surface finish being applied

Finish Options:

- Andodised colour options include silver, black, blue, red and green. Please call to discuss other colour options

- Anti-corrosion coatings: Surtec 650, Iridite NCP or Alocrom 1000 / 1200 can be applied

- Powder coating: Fine texture in black, red or grey are standard but call to discuss other options. We will need to know the RAL number of the colour you are interested in

- Masking parts or all of the rear of the end plate to allow for electrical conductivity is available

Artwork:

Artwork can be applied to the end plates in one of 2 methods.

- Full Colour Digital Print

- Laser Marking

Please note we will require the following:

- For best results we will need you to provide us with logos and images in a vector format.

- A list of all fonts used