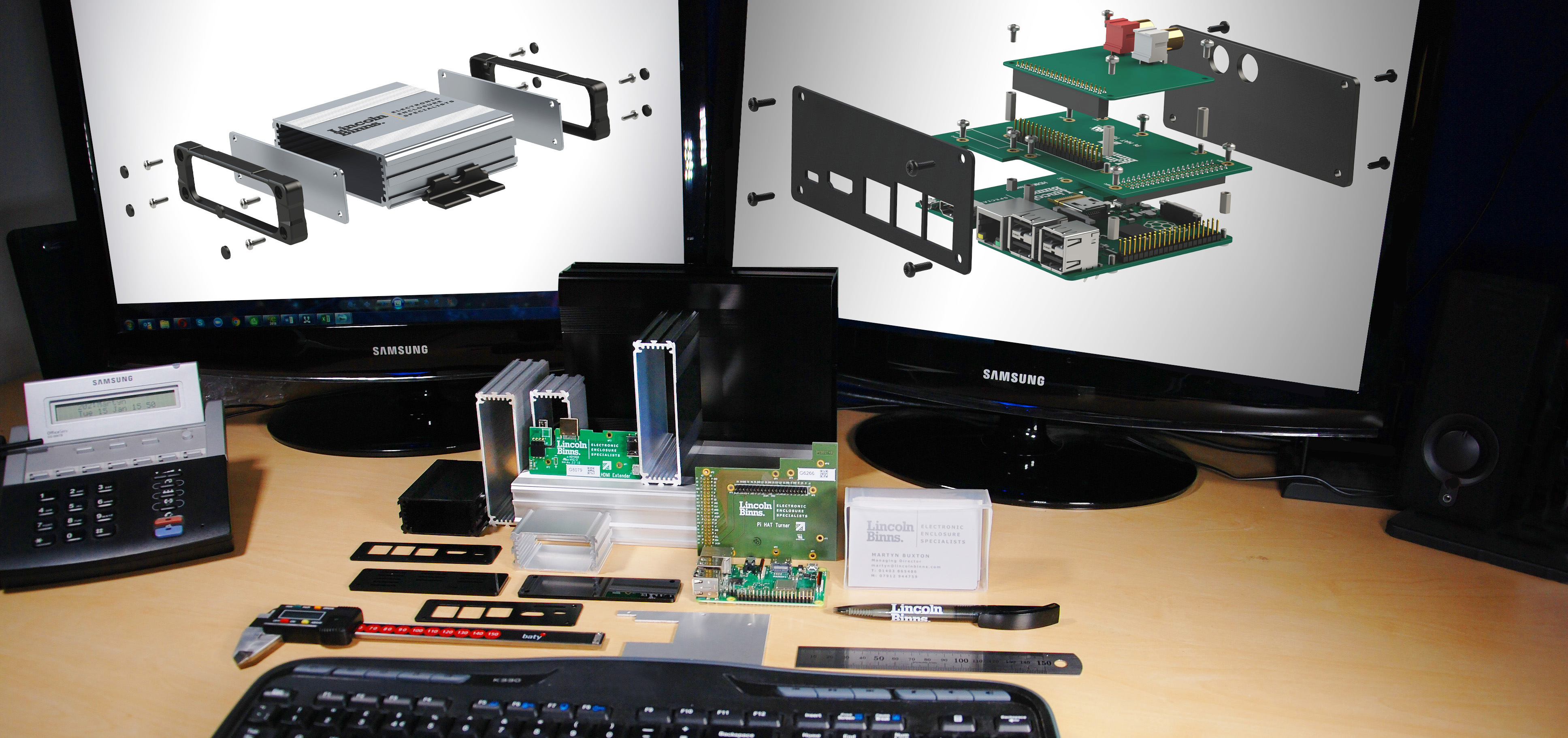

Custom Enclosure Design

Did you know that you can house your electronics in a modified pre-existing enclosure solution such as E-Case, ombi-Case, UnioBox, Alubos, 19” Rack, diecast aluminium or plastic moulded cases?

Designing an enclosure for your new product with Lincoln Binns based on a pre-existing enclosure solution can be done in one of three different ways.

Option One

If you have a clear vision of what you require and can produce a dimensional drawing for the cut-outs and usable artwork then we can work with these to produce your design. To save time going back and forth with phone calls and emails we would require as much information from you as possible.

The dimensional drawing can be anything from a hand drawn sketch up to a full CAD 3D model.

Logos etc need to be in a vector format or equivalent so that we can resize them properly.

A list of components being used in the end panels would allow us to double check your cut-outs against the manufacturer’s recommendations.

We will then send you final drawings for approval prior to being released into production.

We will provide you with STEP, IGES or DXF files for all enclosures, end plates and accessories if required.

Option Two

Send to us your PCB, connectors and any other components and we will work on a few design options based on your outlined requirements.

If you require artwork then we will need your logo in a vector format and a list of fonts that fit your corporate identity.

Throughout the design process we will send you images and 3D PDF’s until a design is agreed.

We will then send you final drawings for approval prior to being released into production.

Option Three

Make an appointment to come in and sit down with the Design & Engineering Manager, talk through your design, have a decent coffee and a few hours later, leave here with a working prototype of your product in your hands.

Lincoln Binns can achieve this as we do all the design and machining in-house. This provides us with the opportunity to offer a rapid prototyping service.

The following services can be provided on site: CNC milling and punching, laser etching and full colour printing.

This will save you weeks of going back and forth via emails and phone calls